I-OEM yakhuthaza ubakaki woxhumano olumise okwe-U

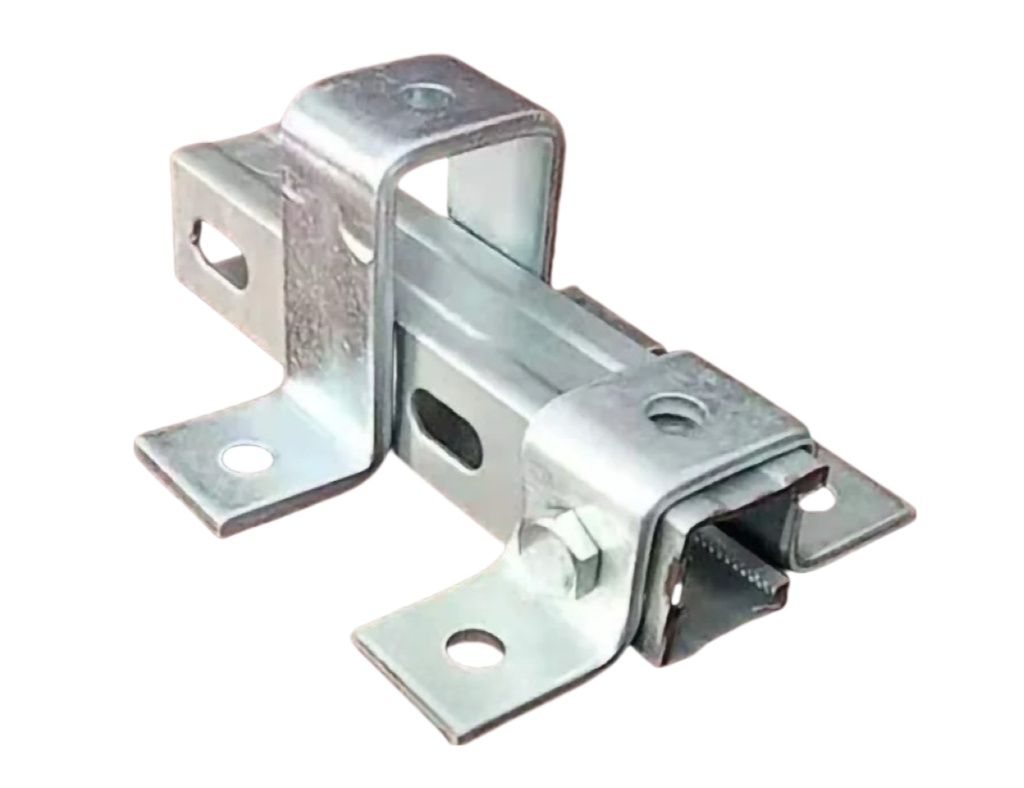

Incazelo

● Ubude: 135 mm

● Ububanzi: 40 mm

● Ubude: 41 mm

● Ubukhulu: 5 mm

● Isimbobo: 12.5 mm

Izinhlobonhlobo zosayizi ziyatholakala.

Ukukhiqizwa okwenziwe ngendlela oyifisayo nakho kuyatholakala ngokusekelwe emidwebeni

| Uhlobo Lomkhiqizo | Imikhiqizo yesakhiwo sensimbi | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta nokwakheka → Ukukhethwa kwezinto → Ukuhanjiswa kwesampula → Ukukhiqizwa ngobuningi → Ukuhlola → Ukwelashwa kwendawo | |||||||||||

| Inqubo | Ukusika i-laser → Ukubhoboza → Ukugoba | |||||||||||

| Izinto zokwakha | Insimbi ye-Q235, insimbi ye-Q345, insimbi ye-Q390, insimbi ye-Q420, insimbi engama-304, insimbi engagqwali engu-316, ingxubevange ye-aluminium engu-6061, ingxubevange ye-aluminium engu-7075. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Isakhiwo sogongolo, insika yesakhiwo, i-truss yesakhiwo, isakhiwo sokusekela ibhuloho, i-Bridge railing, i-Bridge handrail, i-Roof frame, i-Balcony railing, i-Elevator shaft, isakhiwo sengxenye ye-Elevator, uhlaka lwesisekelo semishini yemishini, Isakhiwo sokusekela, ukufakwa kwamapayipi embonini, ukufakwa kwemishini kagesi, Ibhokisi lokusabalalisa, iKhabhinethi yokusabalalisa, Ithreyi yekhebula, ukwakhiwa kombhoshongo wokuxhumana, ukwakhiwa kombhoshongo we-Petrochemical, Ukwakhiwa kombhoshongo we-Petrochemical Subline ukufakwa kwe-reactor, njll. | |||||||||||

Izinzuzo Zokuxhumanisa Okumise Okuka-U Bracket

.Isakhiwo Esilula

Ukwakheka kwesakhiwo sobakaki wokuxhuma okumise okwe-U kulula futhi kucacile, okulula kakhulu futhi okusheshayo ngesikhathi sokufakwa nokusetshenziswa. Awekho amathuluzi ayinkimbinkimbi noma amakhono adingekayo.

Ikhono Elinamandla Lokuthwala

Naphezu komklamo wayo olula, ubakaki woxhumano omise okwe-U usebenza kahle kakhulu ekuthwaleni isisindo kanye nokushuba, futhi ungaqinisekisa ukuthi ulayini noma ipayipi akulula ukunyakaza noma ukuxegiswa lapho ungaphansi kwamandla angaphandle.

.Uhlelo lokusebenza olubanzi

Ubakaki wokuxhuma omise okwe-U ungasetshenziswa kabanzi emikhakheni eminingi, okuhlanganisa kodwa kungagcini nje kuphela embonini yezokwakha, ubunjiniyela bemishini, ezokuthutha, njll., futhi isibe isixhumi esibalulekile kumaphrojekthi namaphrojekthi amaningi.

Inqubo yokukhiqiza

Ukuphathwa Kwekhwalithi

Vickers Ukuqina Instrument

Ithuluzi Lokulinganisa Iphrofayela

I-Spectrograph Instrument

Three Coordinate Instrument

Ukuhlolwa Kwekhwalithi

Izinzuzo Zethu

Indlela eqinile yokuhlolwa kwekhwalithi

I-Xinzhe imise uhlelo oluphelele lokulawula ikhwalithi, oluphelele ngabasebenzi kanye nemishini yokuhlolwa kochwepheshe. Ukuhlolwa nokuhlolwa okuqinile kwenziwa ezintweni ezingavuthiwe, izimpahla eziqedwe kancane, kanye nezimpahla zokugcina. Qiniseka ukuthi izimpahla zinelisa wonke amazinga asebenzayo kanye nezidingo zeklayenti, okuhlanganisa lezo ezihlobene nokunemba kobukhulu, ikhwalithi ephezulu, nezibaluli zomshini.

Umthombo ophakeme wezinto zokusetshenziswa

Izinto ezingavuthiwe eziphezulu zisebenza njengesisekelo sokuqinisekisa ikhwalithi yomkhiqizo futhi zinganciphisa amathuba okuba nezinkinga zekhwalithi emkhiqizweni wokugcina. Sakha ubudlelwano obuhlala njalo nabahlinzeki bempahla eluhlaza ukuze siqinisekise ukuthi izinto zokusetshenziswa—njengamapayipi namashidi ensimbi—ziyikhwalithi engaguquki nokusebenza okuzinzile.

Ukuthuthukiswa kwekhwalithi okuqhubekayo

Sigxila ekuhlaziyeni nasekufingqeni izinkinga zekhwalithi enqubweni yokukhiqiza, ngokuqhubekayo sithuthukisa izinqubo zokukhiqiza nezindlela zokuphatha, kanye nokuthuthukisa ukuzinza nokuvumelana kwekhwalithi yomkhiqizo. Ngokuthuthuka kwekhwalithi okuqhubekayo, singathuthukisa ukwaneliseka nokwethenjwa kwamakhasimende.

Ukupakisha kanye Nokulethwa

I-Angle Steel Bracket

Ubakaki Wensimbi one-engeli yesokudla

Ipuleti Lokuxhuma Umzila Wesitimela

Izesekeli Zokufaka I-Elevator

Ubakaki Omise okwe-L

I-Square Connecting Plate

FAQ

Q: Ingabe imishini yakho yokusika i-laser ingenisiwe?

A: Sinemishini yokusika i-laser ethuthukisiwe, eminye yayo ethengwa kwamanye amazwe.

Q:Kunembe kangakanani?

A:Ukunemba kwethu kokusika i-laser kungathola izinga eliphezulu kakhulu, ngamaphutha avame ukwenzeka phakathi kuka-±0.05mm.

Q:Ingabe ishidi lensimbi eliwugqinsi lingasikwa?

A: Iyakwazi ukusika amashidi ensimbi anobukhulu obuhlukahlukene, kusukela ephepheni elincanyana kuya kumashumi amaningana amamilimitha awugqinsi. Uhlobo lwento kanye nemodeli yemishini inquma ububanzi obunembile bokujiya obungasikwa.

Q: Ngemuva kokusika i-laser, injani ikhwalithi yomkhawulo?

A: Asikho isidingo sokuqhubeka nokucutshungulwa ngoba imiphetho ayina-burr futhi ibushelelezi ngemva kokusika. Kuqinisekiswa kakhulu ukuthi imiphetho yomibili iqondile futhi iyisicaba.