Izinsimbi zamapayipi ensimbi enamapayipi okufaka amabhilidi

● Ubude: 147 mm

● Ububanzi: 147 mm

● Ubukhulu: 7.7 mm

● Ububanzi bembobo: 13.5 mm

Kungenziwa ngezifiso ngesicelo

| Uhlobo Lomkhiqizo | Imikhiqizo yesakhiwo sensimbi | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta nokwakheka → Ukukhethwa kwezinto → Ukuhanjiswa kwesampula → Ukukhiqizwa ngobuningi → Ukuhlola → Ukwelashwa kwendawo | |||||||||||

| Inqubo | Ukusika i-laser → Ukubhoboza → Ukugoba | |||||||||||

| Izinto zokwakha | Insimbi ye-Q235, insimbi ye-Q345, insimbi ye-Q390, insimbi ye-Q420, insimbi engama-304, insimbi engagqwali engu-316, ingxubevange ye-aluminium engu-6061, ingxubevange ye-aluminium engu-7075. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Isakhiwo sogongolo, insika yesakhiwo, i-truss yesakhiwo, isakhiwo sokusekela ibhuloho, i-Bridge railing, i-Bridge handrail, i-Roof frame, i-Balcony railing, i-Elevator shaft, isakhiwo sengxenye ye-Elevator, uhlaka lwesisekelo semishini yemishini, Isakhiwo sokusekela, ukufakwa kwamapayipi embonini, ukufakwa kwemishini kagesi, Ibhokisi lokusabalalisa, iKhabhinethi yokusabalalisa, Ithreyi yekhebula, ukwakhiwa kombhoshongo wokuxhumana, ukwakhiwa kombhoshongo we-Petrochemical, Ukwakhiwa kombhoshongo we-Petrochemical Subline ukufakwa kwe-reactor, njll. | |||||||||||

Umsebenzi wezinsimbi zamapayipi ensimbi

Lungisa indawo yepayipi ukuze uqinisekise ukuzinza kwesistimu yamapayipi nokuwumisa ukuthi unganyakazi ngenkathi usebenza.

Phatha isisindo sepayipi, hambisa isisindo sepayipi esakhiweni esisekelayo ukuze ukhulule ubunzima engxenyeni yokuxhuma yepayipi.

Nciphisa ukudlidliza kwepayipi ngokumunca ukudlidliza kanye nomthelela, kanye nokunciphisa umsindo ewenzayo ngenkathi isebenza kanye nemiphumela yako ezakhiweni eziseduze.

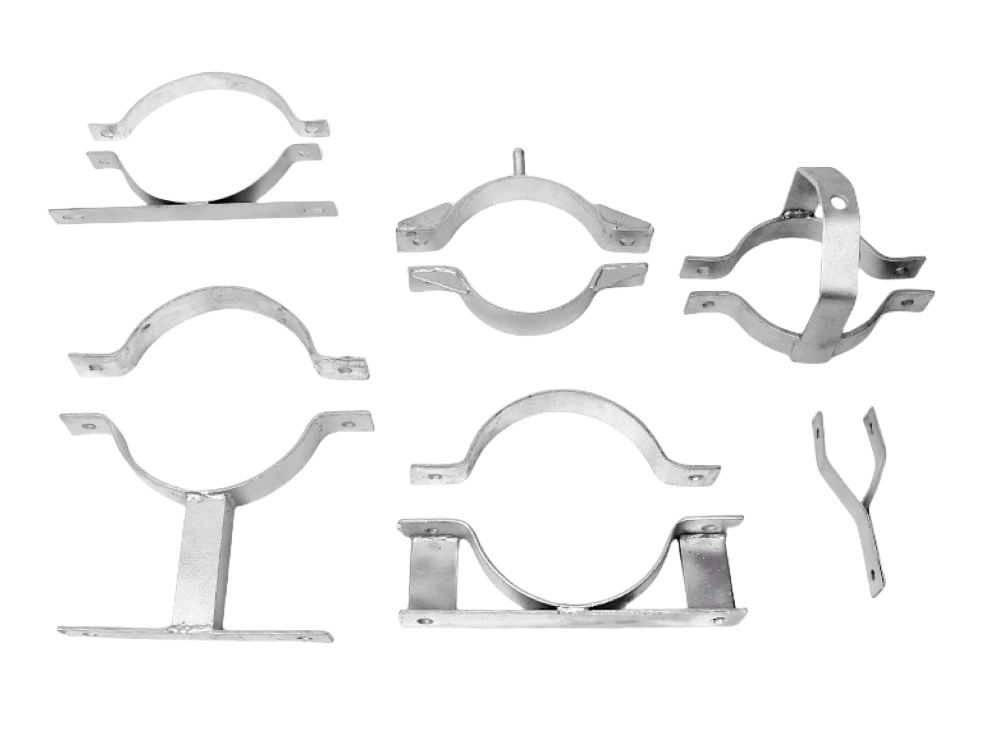

izinhlobo zamapayipi amapayipi

Ngempahla:

Izinsimbi zensimbi:njengezinsimbi zensimbi, amandla aphezulu, ukuqina okuhle, ezifanele amapayipi embonini ahlukahlukene.

Izinsimbi zePlastiki:isisindo esilula, ukumelana nokugqwala, ukufakwa kalula, okuvame ukusetshenziswa emanzini kanye namapayipi okukhipha amanzi, njll.

Ngomumo:

Izinsimbi ezimise okwe-U:I-U-shaped, eboshwe ngama-bolts noma amantongomane, afanele amapayipi ayindilinga.

Ama-clamps annular:Iyindandatho yonke. Ngaphambi kokujoyina, kufanele ihlakazwe futhi ibekwe phezu kwepayipi. Isebenza kahle ngamapayipi amakhulu obubanzi.

Ukuphathwa Kwekhwalithi

Vickers Ukuqina Instrument

Ithuluzi Lokulinganisa Iphrofayela

I-Spectrograph Instrument

Three Coordinate Instrument

Izindlela zokufaka ezivamile zezinsimbi zamapayipi

Okokuqala, nquma indawo yokufaka ipayipi kanye nokucaciswa kanye namamodeli we-clamps yamapayipi, futhi ulungiselele amathuluzi adingekayo nezinto zokwakha, njengama-wrenches, ama-bolts, amantongomane, ama-gaskets, njll.

Okwesibili, faka i-clamp yepayipi epayipi bese ulungisa indawo ukuze i-clamp yepayipi ihambisane ngokuqinile nepayipi. Bese usebenzisa amabhawudi noma amantongomane ukuze uqinise i-clamp yepayipi. Naka amandla okuqinisa amaphakathi, okufanele aqinisekise ukuthi i-clamp ilungisa ipayipi ngokuqinile, kodwa ingaqinile kakhulu ukuze idale umonakalo epayipi.

Ekugcineni, ngemva kokuqedwa kokufakwa, hlola ukuthi i-clamp ifakwe ngokuqinile yini nokuthi ipayipi likhululekile noma lisusiwe. Uma kukhona inkinga, yilungise futhi uyilungise ngesikhathi.

Lapho ufaka futhi unakekela i-clamp yepayipi, naka ukuphepha ukuze ugweme izingozi.

Ukupakisha kanye Nokulethwa

I-Angle Steel Bracket

Ubakaki Wensimbi one-engeli yesokudla

Ipuleti Lokuxhuma Umzila Wesitimela

Izesekeli Zokufaka I-Elevator

Ubakaki Omise okwe-L

I-Square Connecting Plate

FAQ

Q: Ingabe imishini yakho yokusika i-laser ingenisiwe?

A: Sinemishini yokusika i-laser ethuthukisiwe, eminye yayo ethengwa kwamanye amazwe.

Q:Kunembe kangakanani?

A:Ukunemba kwethu kokusika i-laser kungathola izinga eliphezulu kakhulu, ngamaphutha avame ukwenzeka phakathi kuka-±0.05mm.

Q:Ingabe ishidi lensimbi eliwugqinsi lingasikwa?

A: Iyakwazi ukusika amashidi ensimbi anobukhulu obuhlukahlukene, kusukela ephepheni elincanyana kuya kumashumi amaningana amamilimitha awugqinsi. Uhlobo lwento kanye nemodeli yemishini inquma ububanzi obunembile bokujiya obungasikwa.

Q: Ngemuva kokusika i-laser, injani ikhwalithi yomkhawulo?

A: Asikho isidingo sokuqhubeka nokucutshungulwa ngoba imiphetho ayina-burr futhi ibushelelezi ngemva kokusika. Kuqinisekiswa kakhulu ukuthi imiphetho yomibili iqondile futhi iyisicaba.