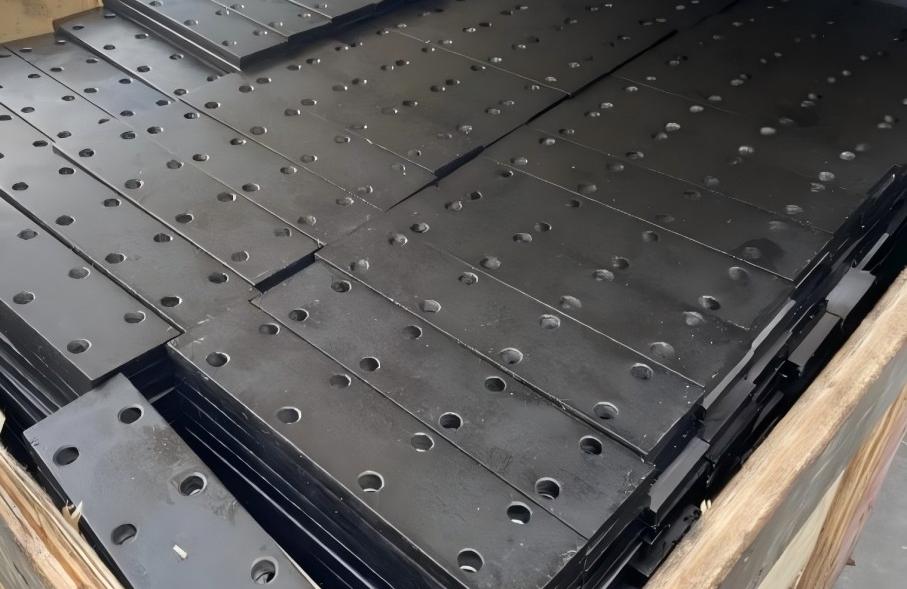

I-Laser yokusika iipleyiti zentsimbi ezifakwe kwi-galvanized square kwizakhiwo

Inkcazo

● Ubude: 115 mm

● Ububanzi: 115 mm

● Ukutyeba: 5 mm

● Ubude besithuba somngxuma: 40 mm

● Ububanzi besithuba somngxuma: 14 mm

Ukwenza ngokwezifiso kuyafumaneka xa uceliwe.

| Uhlobo lweMveliso | Iimveliso ezenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-Ukhetho lwezinto-Ukuhanjiswa kweSampuli-Imveliso yobuninzi-Ukuhlola-unyango lwangaphandle | |||||||||||

| Inkqubo | Laser cutting-Punching-Bending-Welding | |||||||||||

| Izinto eziphathekayo | Intsimbi ye-Q235, intsimbi ye-Q345, insimbi ye-Q390, i-Q420 insimbi, i-304 insimbi engenasici, i-316 insimbi engenasici, i-6061 i-aluminium alloy, i-7075 i-alloy aluminium. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | isakhiwo umqadi isakhiwo, Isakhiwo intsika, truss Building, isakhiwo inkxaso Bridge, Bridge kaloliwe, Bridge handrail, Roof isakhelo, Balcony railing, shaft Elevator, Elevator icandelo isakhiwo, Mechanical isixhobo isiseko isakhelo, Ulwakhiwo Inkxaso, ufakelo Umbhobho Industrial, ufakelo izixhobo zombane, ibhokisi Distribution, Ikhabhinethi Distribution, itreyi Cable, Unxibelelwano inqaba ukwakhiwa umbhobho, Ulwakhiwo lwesakhelo Ulwakhiwo isikhululo sonxibelelwano Petrochemical inqaba ukwakhiwa, Ulwakhiwo lwesakhelo sonxibelelwano, isiseko sonxibelelwano lwePetrochemical ufakelo lwe-reactor, izixhobo zamandla elanga, njalo njalo. | |||||||||||

Iingenelo

● Ukusebenza kweendleko eziphezulu

●Ufakelo olulula

●Umthamo ophezulu wokuthwala

●Ukumelana nomhlwa okuqinileyo

●Uzinzo oluhle

●Ukusebenza kakuhle kweendleko

● Uluhlu olubanzi lwesicelo

Kutheni usebenzisa iipleyiti ezifakwe kwigalvanized?

1. Qinisekisa ukuqina koqhagamshelwano

Ukufakwa kwikhonkrithi ukwenza i-fulcrum eqinile: I-plate edibeneyo igxininiswe kwikhonkrithi ngokusebenzisa i-anchors okanye ngokuthe ngqo, kwaye yenza indawo yokuxhasa eqinile emva kokuba ikhonkrithi iqina. Xa kuthelekiswa nemingxuma yokugrumba okanye ukongeza iinxalenye zenkxaso kamva, ipleyiti edibeneyo inokumelana noxinzelelo olukhulu kunye namandla okucheba.

Gwema ukukhulula kunye ne-offset: Ekubeni i-plate edibeneyo igxininiswe xa igalela ikhonkrithi, ayiyi kukhululeka ngenxa yokunyakaza kunye namandla angaphandle njengezixhumi ezongeziweyo kamva, ngaloo ndlela ziqinisekisa ngcono ukuzinza kwesakhiwo sensimbi.

2. Ukuququzelela ukufakwa kwamacandelo ensimbi

Ngokuphelisa imfuneko yokulinganisa ngokuphindaphindiweyo kunye nokubeka ngexesha lokwakha, iintsimbi zentsimbi, izibiyeli, kunye nezinye izinto zentsimbi zinokudityaniswa ngokuthe ngqo okanye zifakwe kwi-plate yokufaka ngeebholiti, ukuphucula ukusebenza kakuhle kokwakhiwa kunye nokunciphisa iindleko zomsebenzi kunye nexesha.

Ukuze kuncitshiswe nayiphi na imiphumo enokubakho kumandla olwakhiwo, akukho mingxunya ekufuneka igrunjwe kwikhonkrithi egalelweyo ngelixa ufaka ulwakhiwo lwentsimbi kuba ipleyiti yokufaka inemingxunya echongiweyo yoqhagamshelo okanye imiphezulu yewelding ngokwemizobo yoyilo.

3. Ukuziqhelanisa noxinzelelo oluphezulu kunye neemfuno zamandla athile

Ukusabalalisa umthwalo: Kwiindawo eziphambili zeebhulorho kunye nezakhiwo, iiplati ezifakwe ngaphakathi zinokunceda ukusabalalisa imithwalo yesakhiwo, ukuhambisa imithwalo ngokulinganayo kwizakhiwo zekhonkrithi, ukunciphisa ukuxinzezeleka koxinzelelo lwendawo, kunye nokuthintela amacandelo esakhiwo sensimbi ukuba aphule ngenxa yoxinzelelo olugqithiseleyo.

Ukubonelela ukukhupha kunye nokuxhatshazwa kwe-shear: iipleyiti ezifakwe ngaphakathi zivame ukusetyenziswa kunye neehange ukuxhathisa imikhosi ephezulu yokukhupha kunye ne-shear, ebaluleke kakhulu kwiindawo ezinoxinzelelo oluphezulu ezifana nezakhiwo ezinamabali amaninzi, iibhulorho kunye neziseko zezixhobo.

4. Ziqhelanise noyilo oluntsonkothileyo lwesakhiwo

Ukusetyenziswa okuguquguqukayo kwizakhiwo eziyinkimbinkimbi kunye nezingaqhelekanga: Ubukhulu kunye nokuma kweplate edibeneyo inokudibaniswa ngokuchanekileyo kunye nesakhiwo esiyinkimbinkimbi kwaye sinokuhlengahlengiswa ngokuguquguqukayo ukuhlangabezana neenkcukacha zoyilo. Ngokomzekelo, kwizakhiwo ezinjengamaqonga ezixhobo kunye nezixhaso zombhobho, ipleyiti edibeneyo inokubekwa ngokuchanekileyo njengoko kufunekayo ukwenza amacandelo adityaniswe ngaphandle komthungo.

5. Ukuphucula ukuqina kwayo yonke iprojekthi

Nciphisa umhlwa kunye neemfuno zokuyigcina: Ipleyiti ebethelelweyo igqunywe ngekhonkrithi kunye negalvanized, ngoko ke zimbalwa iindawo ezivezwe kwindawo ezonakalisayo. Ngolu khuseleko oluphindwe kabini, ubomi benkonzo yeprojekthi bandiswa kakhulu kwaye ukuphindaphinda kokugcinwa kwesakhiwo kuyancipha.

Qinisekisa ukhuseleko lwendawo yokwakha: Ukuqina kweplate edibeneyo kuqinisekisa ukuzinza kunye nokukhuseleka kokufakwa kwesakhiwo sensimbi, ngokukodwa kwimisebenzi ephezulu okanye ukufakwa kwezixhobo ezinkulu. Kunokunciphisa kakhulu ukuba nokwenzeka kweengozi ezinxulumene nokwakhiwa.

Indima yepleyiti edibeneyo efakwe ngamagalvanized kwiprojekthi yesakhiwo sentsimbi ibaluleke kakhulu. Akuyona nje ikhonkco, kodwa kunye nenkxaso kunye nesiqinisekiso sesakhiwo sonke. Idlala indima engenakuphinda ithathelwe indawo ngokubhekiselele kufakelo olulula, ukusebenza kwamandla, ukuqina kunye nokhuseleko.

Ulawulo loMgangatho

Vickers Ubunzima Instrument

Isixhobo sokulinganisa iProfayili

Spectrograph Instrument

Isixhobo sokuNxibelelanisa ezintathu

Iprofayile yekhampani

Indawo yethu yenkonzo igubungela uluhlu olubanzi lwamashishini abandakanya ukwakhiwa, i-elevators, iibhulorho, iimoto, izixhobo zoomatshini, amandla elanga, njl.ISO9001isiqinisekiso kunye nokulawula ngokungqongqo umgangatho wemveliso ukuhlangabezana nemigangatho yamazwe ngamazwe. Ngezixhobo eziphambili kunye namava atyebileyo ekusetyenzweni kwesinyithi, sihlangabezana neemfuno zabathengiizihlanganisi isakhiwo sentsimbi, iipleyiti zokudityaniswa kwezixhobo, izibiyeli zentsimbi, njl. Sizimisele ukuya kwihlabathi jikelele kunye nokusebenza nabavelisi behlabathi ukunceda ukwakhiwa kwebhulorho kunye nezinye iiprojekthi ezinkulu.

Ukupakishwa kunye nokuhanjiswa

I-Angle Steel Bracket

Isibiyeli sentsimbi yasekunene-engile

IsiKhokelo sikaloliwe sokuDibanisa ipleyiti

Izixhobo zoFakelo lwe-Elevator

Isibiyeli esimile okwe-L

Ipleyiti yokuDibanisa yesikwere

FAQ

Umbuzo: Ufumana njani umvuzo?

A: Amaxabiso ethu aya kwahluka ngokwezinto zentengiso ezifana nenkqubo kunye nemathiriyeli.

Emva kokuba inkampani yakho iqhagamshelane nathi ukuze ifumane kwaye ibonelele ngemizobo kunye nolwazi oluphathekayo, siya kukuthumelela ikowuti yamva nje.

Q:Ngobuphi ubuncinci be-odolo yakho?

A: Ubungakanani obuncinci be-odolo yeemveliso zethu ezincinci ziingcezu ezili-100, kwaye ubuncinci be-odolo yobuninzi beemveliso ezinkulu ziziqwenga ezili-10.

Q:Iza kuthatha ixesha elingakanani ukuthumela ngenqanawa emva kokufaka iodolo?

A: Ixesha lokuhanjiswa kwesampuli malunga neentsuku ze-7 emva kokuhlawula.

Ixesha lokuhanjiswa kwemveliso yobuninzi yi-35-40 iintsuku emva kokufumana intlawulo.