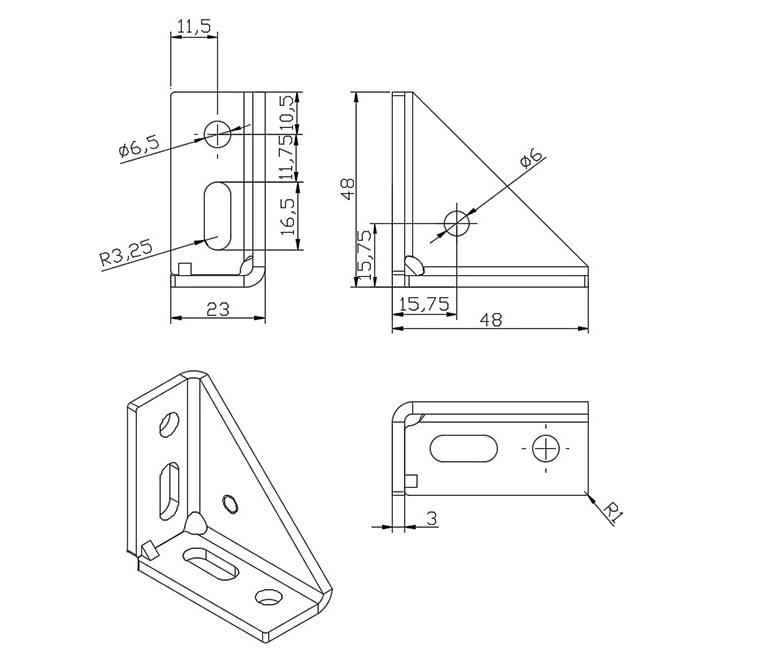

Stainless steel corner brackets for mounting and support

● Material: carbon steel, alloy steel, stainless steel

● Surface treatment: galvanized

● Connection method: fastener connection

● Length: 48mm

● Width: 48mm

● Thickness: 3mm

Customization supported

Features and advantages of angle corner bracket

● Made of high-quality stainless steel, it has excellent corrosion resistance and oxidation resistance, suitable for indoor and outdoor use.

● The carefully designed structure ensures that the bracket remains stable under high-intensity use conditions.

● The smooth surface and delicate edge treatment enhance the overall aesthetics and reduce safety hazards during use.

● A variety of sizes and thicknesses are available to meet different installation needs.

● The reserved screw hole design is compatible with a variety of installation methods (screws, bolts or welding).

● The stainless steel material ensures long-term use and reduces maintenance costs.

● Designed for different load requirements, suitable for light to heavy support.

Application scenarios of angle corner bracket

Construction: Used to fix frames, beams or wall structures to enhance overall support.

Furniture manufacturing: Commonly used in reinforced connections of tables, chairs, cabinets and wooden or metal furniture.

Mechanical equipment: As equipment support to ensure stable operation.

Other fields: Such as gardening brackets, decorative fixings, ship support and other occasions.

Our Advantages

Standardized production, lower unit cost

Scaled production: using advanced equipment for processing to ensure consistent product specifications and performance, significantly reducing unit costs.

Efficient material utilization: precise cutting and advanced processes reduce material waste and improve cost performance.

Bulk purchase discounts: large orders can enjoy reduced raw material and logistics costs, further saving budget.

Source factory

simplify the supply chain, avoid the turnover costs of multiple suppliers, and provide projects with more competitive price advantages.

Quality consistency, improved reliability

Strict process flow: standardized manufacturing and quality control (such as ISO9001 certification) ensure consistent product performance and reduce defective rates.

Traceability management: a complete quality traceability system is controllable from raw materials to finished products, ensuring that bulk purchased products are stable and reliable.

Highly cost-effective overall solution

Through bulk procurement, enterprises not only reduce short-term procurement costs, but also reduce the risks of later maintenance and rework, providing economical and efficient solutions for projects.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Packaging and Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

What are the common corner brackets?

1. Standard L-shaped corner bracket

Features: right-angle design with fixing holes.

Application scenarios: furniture assembly, woodworking frame reinforcement, simple connection.

2. Ribbed reinforced corner bracket

Features: There are reinforcing ribs on the outside of the right angle to enhance the bearing capacity.

Application scenarios: load-bearing furniture, building frames, industrial equipment support.

3. Adjustable corner bracket

Features: Contains movable parts, angle and length can be adjusted according to needs.

Application scenarios: photovoltaic bracket installation, adjustable shelves, non-standard angle connection.

4. Hidden corner bracket

Features: hidden design, simple appearance after installation without revealing the bracket.

Application scenarios: wall hanging decoration, hidden bookshelf, cabinet installation.

5. Decorative corner bracket

Features: focus on appearance design, usually with decorative carvings or polished surfaces.

Application scenarios: corner decoration, home decoration, display rack.

6. Heavy-duty corner bracket

Features: heavier structure, suitable for large loads and high-strength applications.

Application scenarios: mechanical equipment support, bridge construction, steel structure installation.

7. Right-angle connection plate angle bracket

Features: flatter and low-profile, suitable for reinforced connection of thin plate structure.

Application scenarios: sheet metal equipment, frame welding, pipe support.

8. Arc or bevel angle bracket

Features: The corners are designed with arcs or bevels to reduce stress concentration or increase decorativeness.

Application scenarios: elevator mounting brackets, equipment protection parts.

9. T-shaped or cross-shaped angle bracket

Features: Designed in a "T" or cross shape for multi-directional connection.

Application scenarios: fixed connection at the intersection of frames, large shelf installation.

10. Shockproof or anti-slip angle bracket

Features: The bracket is attached with shockproof rubber pads or textured surfaces to reduce vibration or sliding.

Application scenarios: mechanical equipment fixing, elevator systems, industrial installation parts.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation