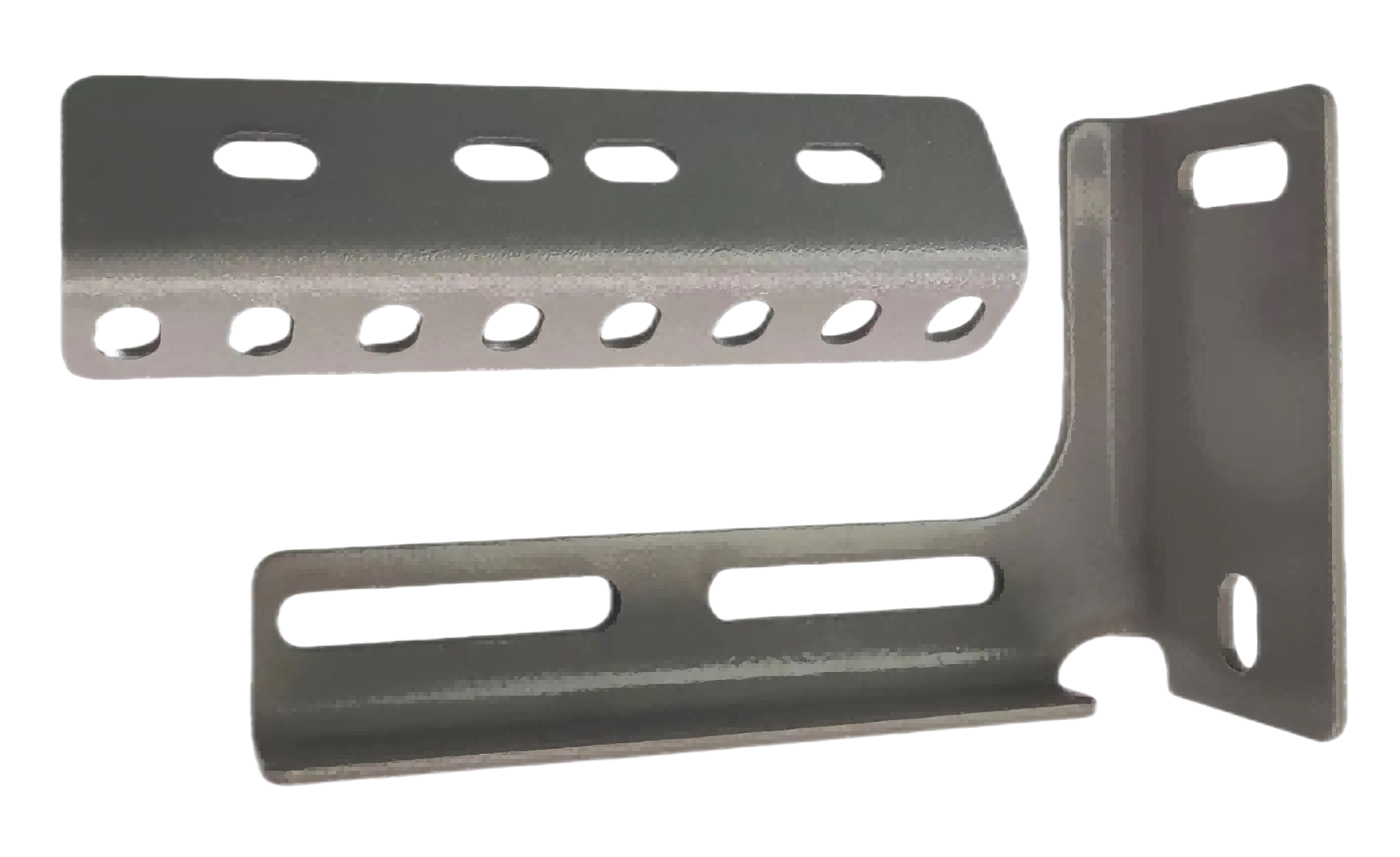

Stainless Steel brackets of guide rail For Hitachi Elevator

● Length: 165 - 215 mm

● Width: 45 mm

● Height: 90 - 100 mm

● Thickness: 4 mm

● Hole length: 80 mm

● Hole width: 8 mm - 13 mm

● Product type: Elevator spare parts

● Material: Stainless steel, carbon steel, alloy steel

● Process: Laser cutting, bending, punching

● Surface treatment: Galvanizing, anodizing

● Application: Fixing, connecting

● Weight: About 3.8KG

Product Advantages

Sturdy structure: Made of high-strength steel, it has excellent load-bearing capacity and can withstand the weight of elevator doors and the pressure of daily use for a long time.

Precise fit: After precise design, they can perfectly match various elevator door frames, simplify the installation process and reduce commissioning time.

Anti-corrosion treatment: The surface is specially treated after production, which has corrosion and wear resistance, suitable for various environments, and prolongs the service life of the product.

Diverse sizes: Custom sizes can be provided according to different elevator models.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Characteristics of elevator brackets as rigid brackets

High strength and low deformation

● Elevator brackets are usually made of high-strength materials (such as carbon steel, stainless steel or aluminum alloy), which can withstand the load of elevator guide rails, cars and counterweight systems, and will not deform significantly during operation.

Earthquake resistance

● Since elevators may encounter earthquakes or vibrations generated during operation, brackets usually need to be strictly designed and processed to have good earthquake resistance, and belong to the type of rigid brackets with higher safety requirements.

Fixing function

● Elevator guide rail brackets (such as guide rail fixing brackets or mounting brackets) need to firmly fix the guide rails on the shaft wall to ensure that the guide rails can stably guide the car to run. This type of bracket cannot allow any looseness or offset, which fully reflects the fixing characteristics of the rigid bracket.

Diversified design

● Elevator brackets may include L-shaped brackets, curved brackets, mounting bases, etc., which not only require support functions, but also need to meet the requirements of compact installation space. Each type of bracket is specially designed to maximize rigidity and stability.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-channel brackets, angle brackets, galvanized embedded base plates, elevator mounting brackets and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment in conjunction with bending, welding, stamping, surface treatment, and other production processes to guarantee the precision and longevity of the products.

As an ISO 9001 certified company, we have worked closely with many international machinery, elevator and construction equipment manufacturers and provide them with the most competitive customized solutions.

According to the company's "going global" vision, we are dedicated to offering top-notch metal processing services to the global market and are constantly working to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

What are the service life of rigid brackets and elastic brackets?

Rigid bracket

Service life factors

● Material quality: Use high-quality steel (such as Q235B or Q345B) and meet the specifications. It can be used for 20-30 years in normal indoor environment.

● Load conditions: Use within the design load range, such as ordinary residential elevators, and the service life is longer; frequent overloading will shorten the service life to 10-15 years or even shorter.

● Environmental factors: In a dry and clean indoor environment, corrosion damage is small; in a humid and corrosive gas environment, if no anti-corrosion measures are taken, serious corrosion may occur in about 10-15 years.

● The impact of maintenance on service life: Regular maintenance, such as checking and tightening bolts, surface cleaning and anti-corrosion treatment, can extend the service life.

Elastic bracket

Service life factors

● Elastic element characteristics: The service life of rubber shock pads is about 5-10 years, and the service life of springs is about 10-15 years, which is affected by the material and working stress.

● Working environment and working conditions: In environments with large temperature and humidity changes and in elevators that operate frequently, the aging and fatigue damage of elastic components are accelerated. For example, the elastic components of elevators in large commercial centers may need to be replaced every 5 to 8 years.

● The impact of maintenance on life: Regularly check and replace damaged elastic components in a timely manner. Proper maintenance can extend the service life to about 10 to 15 years.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation