Lisebelisoa tsa lipeipi tsa galvanized bakeng sa ho haha

● Bolelele: 147 mm

● Bophara: 147 mm

● Botenya: 7,7 mm

● Bophara ba lesoba: 13.5 mm

E ka etsoa ho latela kopo

| Mofuta oa Sehlahisoa | Lihlahisoa tsa tšepe tsa mohaho | |||||||||||

| Tšebeletso e le 'ngoe | Kholiso ea hlobo le moralo → Khetho ea thepa → Tlhahiso ea mohlala → Tlhahiso e ngata → Tlhahlobo → Phekolo ea bokaholimo | |||||||||||

| Tshebetso | Ho itšeha ka laser → Ho phunya → Ho kobeha | |||||||||||

| Lisebelisoa | Q235 tšepe, Q345 tšepe, Q390 tšepe, Q420 tšepe, 304 tšepe e sa hloekang, 316 tšepe e sa hloekang, 6061 alloy alloy, 7075 aluminium motsoako. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Mohaho oa sefate sa mohaho, tšiea ea mohaho, mohaho oa mohaho, mohaho oa tšehetso ea borokho, seporo sa borokho, letsoho la borokho, foreimi ea marulelo, liporo tsa Balcony, mochini oa Elevator, mohaho oa karolo ea Elevator, mochini oa thepa ea motheo, mohaho oa ts'ehetso, ts'ebetso ea lipeipi tsa indasteri, lisebelisoa tsa motlakase, lebokose la kabo, khabinete ea kabo, terei ea cable, mohaho oa tora ea motlakase, setsi sa puisano sa Petrochemical tlhomamiso ea reactor, joalo-joalo. | |||||||||||

Mosebetsi oa liphaephe tsa tšepe tsa tšepe

Lokisa boemo ba phaepe ho netefatsa botsitso ba tsamaiso ea lipeipi le ho e thibela ho tsamaea ha e ntse e sebetsa.

Jara boima ba liphaephe, fetisetsa boima ba phala ho sebopeho se tšehetsang ho fokotsa khatello karolong e hokelang liphaephe.

Fokotsa ho thothomela ha lipeipi ka ho monya ho thothomela le litlamorao, hammoho le ho fokotsa lerata leo e le etsang ha e ntse e sebetsa le litlamorao tsa eona meahong e haufi.

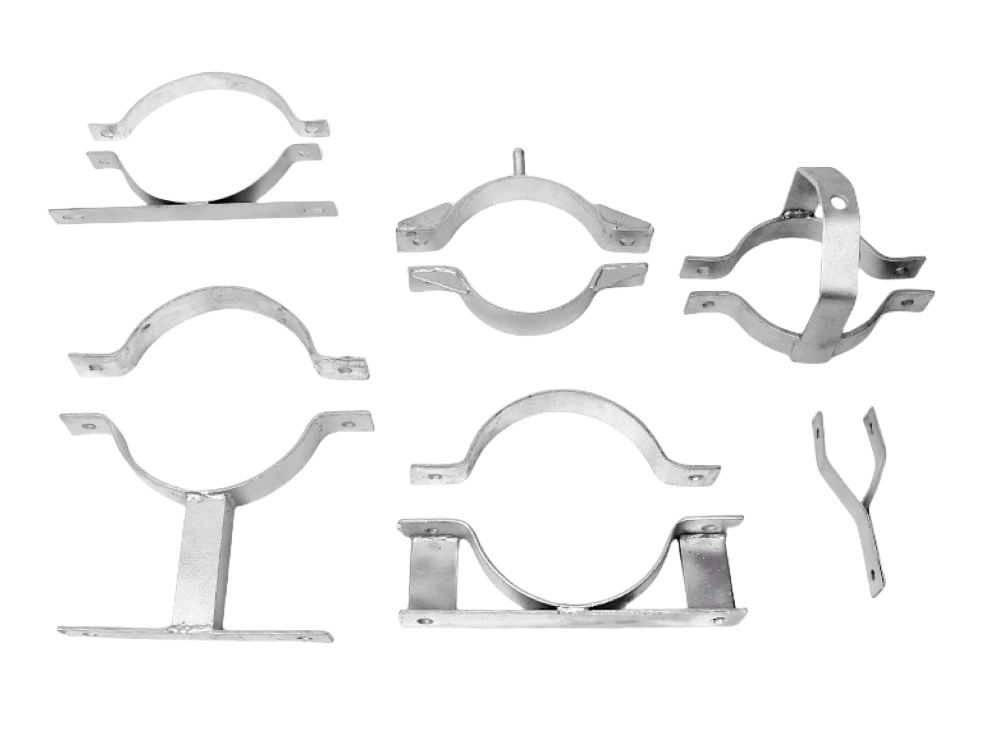

mefuta e sa tšoaneng ea liphaephe

Ka lintho tse bonahalang:

Metal clamps:joalo ka li-clamps tsa tšepe, matla a phahameng, ho tšoarella hantle, tse loketseng liphaephe tse fapaneng tsa indasteri.

Li-clamps tsa polasetiki:boima bo bobebe, ho hanyetsa kutu, ho kenya habonolo, hangata ho sebelisoa phepelong ea metsi le liphaephe tsa drainage, jj.

Ka sebopeho:

Li-clamps tse nang le sebopeho sa U:Sebopeho sa U, se tiisitsoeng ka liboutu kapa linate, tse loketseng liphaephe tse chitja.

Li-clamps tsa annular:Ke mohaho oohle oa selikalikoe. Pele o kopanya, e tlameha ho qhaqhoa ebe e behoa phala. E sebetsa hantle ka liphaephe tse kholoanyane tsa bophara.

Tsamaiso ea Boleng

Vickers Hardness Instrument

Seletsa sa Tekanyo ea Boemo

Sesebelisoa sa Spectrograph

Lisebelisoa tse tharo tsa Coordinate

Mekhoa e tloaelehileng ea ho kenya liphaephe tsa liphaephe

Ntlha ea pele, fumana sebaka sa ho kenya phala le litlhaloso le mehlala ea liphaephe tsa liphaephe, 'me u lokise lisebelisoa le lisebelisoa tse hlokahalang, tse kang li-wrenches, bolts, linate, li-gaskets, joalo-joalo.

Taba ea bobeli, beha phala ea phala holim'a phala 'me u lokise boemo e le hore clamp ea pipe e lumellane ka thata le phala. Ebe u sebelisa liboutu kapa linate ho tiisa phala. Ela hloko matla a ho tiisa ka mokhoa o itekanetseng, a lokelang ho etsa bonnete ba hore clamp e tiisa phala ka thata, empa e se thata haholo ho baka tšenyo ea pipe.

Qetellong, ka mor'a hore ho behoe ho phethoe, hlahloba hore na clamp e kentsoe ka thata le hore na pipe e hlephile kapa e falla. Haeba ho na le bothata leha e le bofe, lokisa 'me u bo lokise ka nako.

Ha u kenya le ho boloka clamp ea pipe, ela hloko tšireletso ho qoba likotsi.

Ho paka le ho Romela

Angle Steel Bracket

Bracket ea tšepe e ka ho le letona

Tataiso ea Terene e Hokelang Plate

Lisebelisoa tsa ho kenya Elevator

Bracket e nang le sebopeho sa L

Square Connecting Plate

LBH

P: Na thepa ea hau ea ho itšeha ka laser e tsoa kantle ho naha?

A: Re na le lisebelisoa tse tsoetseng pele tsa ho itšeha ka laser, tseo tse ling tsa tsona e leng thepa ea boleng bo holimo e tsoang kantle ho naha.

P: E nepahetse hakae?

A: Ho nepahala ha rona ka laser ea ho itšeha ho ka fihlela boemo bo holimo haholo, ka liphoso tse etsahalang hangata ka har'a ± 0.05mm.

P: Letlapa le letenya la tšepe le ka khaoloa joang?

A: E khona ho seha lishiti tsa tšepe tse nang le botenya bo fapaneng, ho tloha ho pampiri e tšesaane ho isa ho mashome a 'maloa a limilimithara tse teteaneng. Mofuta oa thepa le mohlala oa lisebelisoa li khetholla mofuta o nepahetseng oa botenya o ka sehiloeng.

P: Ka mor'a ho itšeha ka laser, boleng ba bohale bo joang?

A: Ha ho na tlhoko ea ts'ebetso e 'ngoe hape hobane mathoko ha a na burr ebile a boreleli kamora ho seha. Ho netefalitsoe haholo hore mats'oafo a tsepame ebile a bataletse.