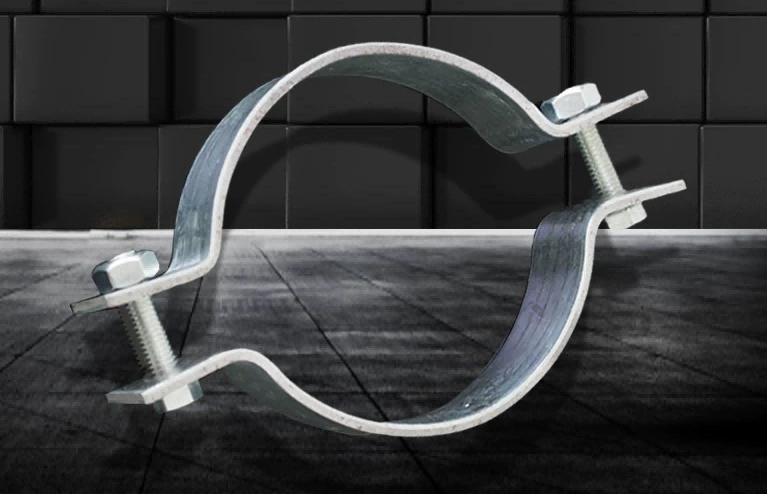

Bracket e Tloaelehileng ea Pipe Clamp Clamp

Tlhaloso

Pipe Support Bracket litekanyo bakeng sa phala bophara 250 limilimithara

● Kakaretso ea bolelele: 322 mm

● Bophara: 30 mm

● Botenya: 2 mm

● Ho arohana ha lesoba: 298 mm

| Mohlala No. | Pipe Diameter Range | Bophara | Botenya | Boima ba 'mele |

| 001 | 50-80 | 25 | 2 | 0.45 |

| 002 | 80-120 | 30 | 2.5 | 0.65 |

| 003 | 120-160 | 35 | 3 | 0.95 |

| 004 | 160-200 | 40 | 3.5 | 1.3 |

| 005 | 200-250 | 45 | 4 | 1.75 |

| Mofuta oa Sehlahisoa | Lihlahisoa tsa tšepe tsa mohaho | |||||||||||

| Tšebeletso e le 'ngoe | Kholiso ea hlobo le moralo → Khetho ea thepa → Tlhahiso ea mohlala → Tlhahiso e ngata → Tlhahlobo → Phekolo ea bokaholimo | |||||||||||

| Tshebetso | Ho itšeha ka laser → Ho phunya → Ho kobeha | |||||||||||

| Lisebelisoa | Q235 tšepe, Q345 tšepe, Q390 tšepe, Q420 tšepe, 304 tšepe e sa hloekang, 316 tšepe e sa hloekang, 6061 alloy alloy, 7075 aluminium motsoako. | |||||||||||

| Litekanyo | ho latela metako kapa disampole tsa moreki. | |||||||||||

| Qetella | Fafatsa pente, electroplating, hot-dip galvanizing, ho roala phofo, electrophoresis, anodizing, blackening, joalo-joalo. | |||||||||||

| Sebaka sa Kopo | Mohaho oa sefate sa mohaho, tšiea ea mohaho, mohaho oa mohaho, mohaho oa tšehetso ea borokho, seporo sa borokho, letsoho la borokho, foreimi ea marulelo, liporo tsa Balcony, mochini oa Elevator, mohaho oa karolo ea Elevator, mochini oa thepa ea motheo, mohaho oa ts'ehetso, ts'ebetso ea lipeipi tsa indasteri, lisebelisoa tsa motlakase, lebokose la kabo, khabinete ea kabo, terei ea cable, mohaho oa tora ea motlakase, setsi sa puisano sa Petrochemical tlhomamiso ea reactor, joalo-joalo. | |||||||||||

Melemo ea Kopo

Corrosion resistance:Pipe Clamp e sebelisa tšepe e sa hloekang kapa phekolo e entsoeng ka masenke, e ka mamellang maemo a leholimo a matla, haholo-holo ka ntle.

Seta se bonolo:Ho bonolo ho kopanya, ka potlako le ka mokhoa o bonolo, le ho tenyetseha ho lekana ho amohela liphaephe tsa bophara bo fapaneng.

Bokhoni bo phahameng ba ho jara:E khona ho boloka liphaephe tse nang le li-diameter tse kholoanyane le ho fana ka ts'ebetso e sireletsehileng ha e le tlas'a meroalo e phahameng.

Libaka tse tloaelehileng tsa ts'ebeliso ea Pipe Clamp

Moaho le Meaho

Ho fana ka ts'ehetso e tsitsitseng le e tšoarellang bakeng sa lipeipi tsa metsi tse sa fetoheng, lipeipi tsa khase, likotopo tsa cable, meaho e phahameng, le marang-rang a lipeipi tse ka tlas'a lefatše mererong ea kaho. Sehlopha sa Pipe ea Tšepe, Sekepe sa Galvanized Pipe Clamp kapa Carbon Steel Pipe Clamp se ka netefatsa botsitso ba lipeipi nakong ea kaho le tšebeliso, le ho thibela ho thothomela le ho falla.

Indasteri ea Matla le Lipuisano

Liphaephe tse kholo, lithapo tsa puisano, le lipalo tse ka ntle kaofela li tsitsitse ebile li sirelelitsoe ka Pipe Clamp indastering ea matla le likhokahano. Pipe Clamp e sebetsa hantle haholo bakeng sa ho mamella ho bola le khoholeho e bakoang ke moea le pula maemong a thata a kantle.

Tlhahiso ea Liindasteri le Petrochemicals

Libakeng tsa liindasteri tse kang lifeme le libaka tsa ho hloekisa, Pipe Clamp e sebelisoa ho tšehetsa lipeipi tsa indasteri tse bophara bo boholo ho tsamaisa maro, likhase kapa lik'hemik'hale. Li-brackets tsena li tlameha ho khona ho mamella mocheso o phahameng, likhatello le ho bola ha lik'hemik'hale, 'me Pipe Clamp e entsoeng ka thepa e khethehileng e ntse e sebetsa hantle tlas'a maemo ana.

Lipalangoang le Kaho ea Borokho

Mererong ea lipalangoang, Pipe Clamp e ka boela ea sebelisoa ho lokisa le ho ts'ehetsa lipeipi, litšepe le lisebelisoa tse amanang le eona kahong ea borokho. E thusa ho lokisa le ho sireletsa lits'ebeletso tsa bohlokoa joalo ka liphaephe tsa oli le liphaephe tsa drainage ho netefatsa polokeho ea ts'ebetso ea nako e telele.

Boenjiniere ba Masepala

Kahong ea meralo ea motheo ea masepala, Pipe Clamp e atisa ho sebelisoa ho lokisa lipalo tsa mabone a seterateng le phepelo ea metsi litoropong le lipeipi tsa likhoerekhoere. E ka ntlafatsa ka katleho botsitso le polokeho ea marang-rang a lipeipi tsa litoropo.

Mokhoa oa tlhahiso

Tsamaiso ea Boleng

Vickers Hardness Instrument

Seletsa sa Tekanyo ea Boemo

Sesebelisoa sa Spectrograph

Lisebelisoa tse tharo tsa Coordinate

Melemo ea Rōna

Moralo o ikhethileng:Fana ka lits'ebeletso tsa moralo tse ikhethileng, tse ka fetolang mehopolo ea moralo oa bareki hore e be lihlahisoa tsa 'nete ho fihlela litlhoko tse ikhethang tsa bareki.

Tlhahiso e feto-fetohang:Litokisetso tse feto-fetohang tsa tlhahiso li ka etsoa ho latela boholo ba taelo ea bareki le nako ea ho fana. Ebang ke sehlopha se senyenyane sa litaelo tse hlophisitsoeng kapa sehlopha se seholo sa litaelo tsa tlhahiso, li ka phethoa ka katleho.

Tlhahlobo ea lihokelo tse ngata:Ho tloha tlhahlobong e kenang ea lihlahisoa tse tala, ho ea ho ts'ebetso ea ts'ebetso nakong ea ts'ebetso, ho fihlela tlhahlobo ea ho qetela ea sehlahisoa se felileng, sehokelo se seng le se seng se hlahlojoa ka thata bakeng sa boleng.

Thepa e tsoetseng pele ea tlhahlobo:E na le lisebelisoa tse phahameng tsa ho hlahloba ka mokhoa o nepahetseng, tse kang mechine e methang e meraro, lisebelisoa tsa ho lekanya boima, li-analyzer tsa metallographic, joalo-joalo.

Sistimi ea ho latedisa boleng:Theha mokhoa o felletseng oa ho latedisa boleng, o nang le direkoto tse qaqileng tsa tlhahiso le ditlaleho tsa tlhahlobo ya boleng bakeng sa sehlahiswa ka seng. Motso oa bothata o ka fumanoa ka nako mme oa rarolloa ka lekhetlo la pele.

Ho paka le ho Romela

Angle Steel Bracket

Bracket ea tšepe e ka ho le letona

Tataiso ea Terene e Hokelang Plate

Lisebelisoa tsa ho kenya Elevator

Bracket e nang le sebopeho sa L

Square Connecting Plate

LBH

P: Na thepa ea hau ea ho itšeha ka laser e tsoa kantle ho naha?

A: Re na le lisebelisoa tse tsoetseng pele tsa ho itšeha ka laser, tseo tse ling tsa tsona e leng thepa ea boleng bo holimo e tsoang kantle ho naha.

P: E nepahetse hakae?

A: Ho nepahala ha rona ka laser ea ho itšeha ho ka fihlela boemo bo holimo haholo, ka liphoso tse etsahalang hangata ka har'a ± 0.05mm.

P: Letlapa le letenya la tšepe le ka khaoloa joang?

A: E khona ho seha lishiti tsa tšepe tse nang le botenya bo fapaneng, ho tloha ho pampiri e tšesaane ho isa ho mashome a 'maloa a limilimithara tse teteaneng. Mofuta oa thepa le mohlala oa lisebelisoa li khetholla mofuta o nepahetseng oa botenya o ka sehiloeng.

P: Ka mor'a ho itšeha ka laser, boleng ba bohale bo joang?

A: Ha ho na tlhoko ea ts'ebetso e 'ngoe hape hobane mathoko ha a na burr ebile a boreleli kamora ho seha. Ho netefalitsoe haholo hore mats'oafo a tsepame ebile a bataletse.