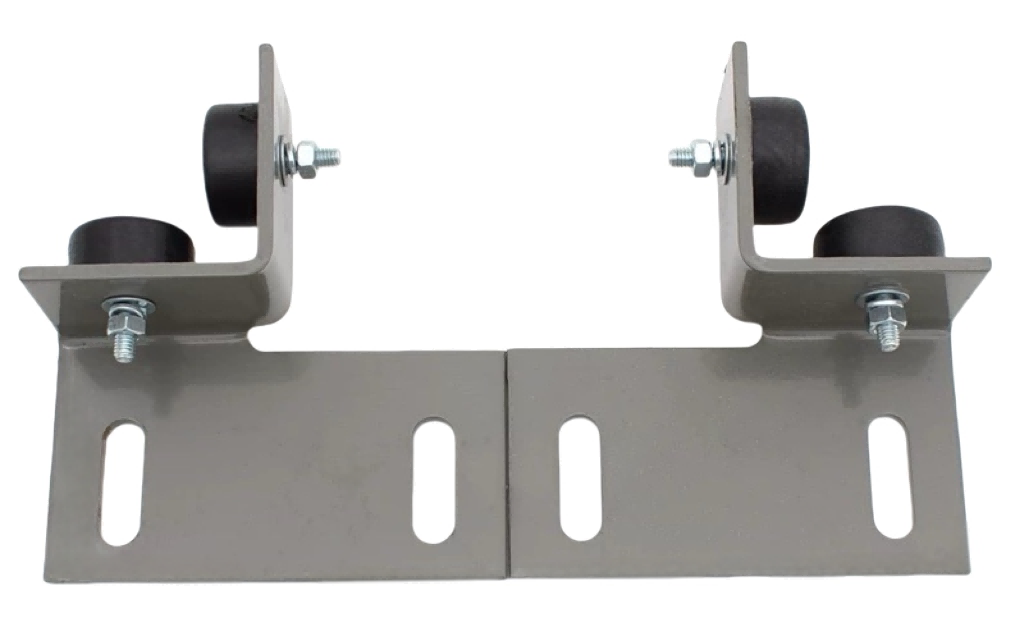

Shock-absorbing pad mounting bracket for elevator car top

● Length: 125 mm

● Width: 64 mm

● Height: 65 mm

● Thickness: 4 mm

● Hole length: 25 mm

● Hole width: 9 mm-14 mm

Commonly used bracket materials

● Q345 steel

This low-alloy high-strength structural steel has a high yield strength. It is relatively more commonly used in large freight elevators or high-speed elevators. After treatment, it has good corrosion resistance and wear resistance.

● 45 steel

Because it is a high-quality carbon structural steel with a high carbon content.

● Aluminum alloy

Such as 6061 aluminum alloy, it is light in weight and high in strength, which can reduce the weight of the top of the car, which is beneficial to energy saving and operation efficiency of the elevator. After anodizing treatment, it has good corrosion resistance, but the hardness is lower than that of steel.

● Copper alloy

For example, brass or bronze has good electrical and thermal conductivity and may be used in special elevator systems. It can reduce friction and wear when lubricants are properly added.

Our Advantages

● Customization capability: Ability to provide personalized solutions based on customer specific needs.

● High efficiency: Advanced equipment and technology improve production efficiency and shorten delivery cycle.

● Quality assurance: Strict quality control system ensures product consistency and reliability.

● Diversified products: A wide range of product lines to meet the needs of different industries.

● Flexibility: Quickly respond to market changes and adapt to different order volumes and complexities.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries.

The main products include metal building brackets, brackets galvanized, fixed brackets, U-shaped slot brackets, angle steel brackets, galvanized embedded base plates, elevator mounting brackets, turbo mounting bracket and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment, combined with bending, welding, stamping, surface treatment and other production processes to ensure the accuracy and service life of the products.

As an ISO9001 certified company, we work closely with many international machinery, elevator and construction equipment manufacturers to provide them with the most competitive customized solutions.

Adhering to the concept of making our bracket solutions serve all over the world, we are committed to providing first-class metal processing services to the global market and constantly strive to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Just send your drawings and required materials to our email or WhatsApp, and we will provide you with the most competitive quote as soon as possible.

Q: What is your minimum order quantity?

A: The minimum order quantity for our small products is 100 pieces, and the minimum order quantity for large products is 10 pieces.

Q: How long do I have to wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

Mass production products are 35 to 40 days after payment.

Q: What is your payment method?

A: We accept payments through bank accounts, Western Union, PayPal or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation