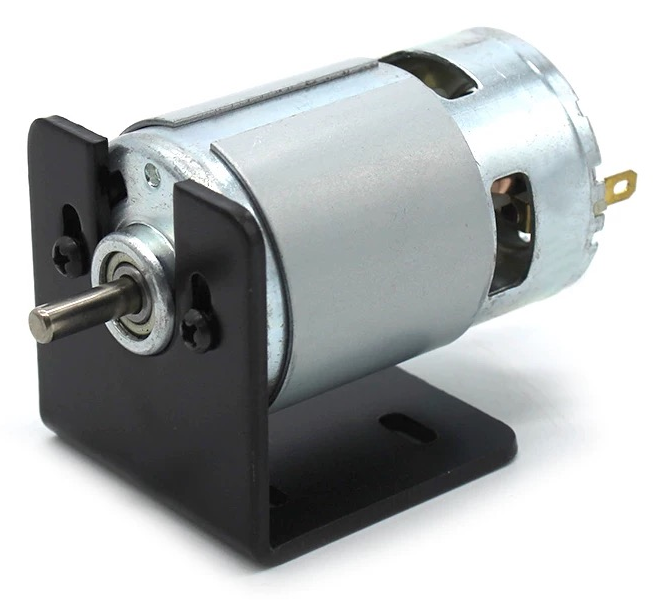

OEM Precision Metal Stamping Parts Motor Mounting Bracket

● Material: carbon steel, alloy steel, stainless steel, aluminum alloy

● Surface treatment: galvanized, blackened

● U-shaped groove cutout depth: 27.5 mm

● U-shaped groove cutout width: 18 mm

● Length: 52 mm

● Width: 50 mm

● Height: 52 mm

● Thickness: 3 mm

The main function of the motor bracket

Support the motor

Bear the weight of the motor and fix its position, such as in industrial plants and mobile equipment, to prevent the motor from sinking or shifting.

Vibration reduction and noise reduction

Buffer the vibration generated by the operation of the motor and reduce noise transmission. For example, the motor bracket of the air conditioner outdoor unit uses shock-absorbing elements or special materials to reduce operating noise.

Adjust the motor position

Allows fine-tuning of the motor in the horizontal and vertical directions to ensure that the motor shaft is aligned with the shaft of other equipment, reduce wear of connecting parts, and improve transmission efficiency. It plays an important role in industrial transmission systems.

Isolate the motor from the installation foundation

Avoid the direct transfer of motor heat to the installation foundation, and also prevent the vibration of the installation foundation from interfering with the motor. It is more obvious in the workshop of precision electronic equipment.

Our Advantages

Standardized production, lower unit cost

Scaled production: using advanced equipment for processing to ensure consistent product specifications and performance, significantly reducing unit costs.

Efficient material utilization: precise cutting and advanced processes reduce material waste and improve cost performance.

Bulk purchase discounts: large orders can enjoy reduced raw material and logistics costs, further saving budget.

Source factory

simplify the supply chain, avoid the turnover costs of multiple suppliers, and provide projects with more competitive price advantages.

Quality consistency, improved reliability

Strict process flow: standardized manufacturing and quality control (such as ISO9001 certification) ensure consistent product performance and reduce defective rates.

Traceability management: a complete quality traceability system is controllable from raw materials to finished products, ensuring that bulk purchased products are stable and reliable.

Highly cost-effective overall solution

Through bulk procurement, enterprises not only reduce short-term procurement costs, but also reduce the risks of later maintenance and rework, providing economical and efficient solutions for projects.

How to choose a suitable motor bracket?

The following factors should be considered when selecting the material of the motor bracket:

Mechanical properties

Strength requirements: Large or high-power motors require high-strength materials, such as cast iron and carbon steel, to withstand vibration, torque and other forces.

Rigidity requirements: To ensure the accuracy of the motor shaft alignment, the bracket must be rigid enough. For example, the motor bracket in machine tool equipment has high rigidity requirements. Aluminum alloy and stainless steel are better choices.

Fatigue performance: Frequent start and stop of the motor causes the bracket to be subjected to alternating stress, which requires materials with good fatigue resistance, such as high-quality alloy steel. For example, the motor bracket of the automobile engine cooling fan requires fatigue resistance.

Physical properties

Density and weight: In areas with weight restrictions (such as aerospace and electric vehicles), aluminum alloys with low density are better choices.

Thermal expansion coefficient: The heat generated by the motor will cause the bracket to expand. In precision instruments and equipment, materials with low thermal expansion coefficients should be selected, such as ceramic materials or low expansion coefficient alloys.

Chemical properties

Corrosion resistance: In humid and corrosive environments, such as chemical workshops and marine ship environments, motor brackets require materials with good corrosion resistance, such as stainless steel and hot-dip galvanized carbon steel.

Chemical stability: The material of the motor bracket should avoid reacting with chemical substances in the environment. In an environment with organic solvents, materials with good chemical stability should be selected.

Cost factors

Material cost: Cast iron and carbon steel are relatively low in cost, while stainless steel and high-performance engineering plastics are high in cost. Civil motor equipment usually considers low-cost materials.

Processing cost: Aluminum alloys and some engineering plastics have good processing performance and can reduce processing costs. High-strength alloy steel is difficult to process and has high costs.

Other factors

Electromagnetic compatibility: In electronic equipment or environments sensitive to electromagnetic interference, non-ferromagnetic materials such as aluminum alloys or certain engineering plastics may be selected.

Appearance requirements: In situations where there are appearance requirements, the material and surface treatment method should be considered. For example, the motor bracket in consumer electronic products may choose materials with good surface quality.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Packaging and Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How can I get a quote?

A: Simply send us your detailed drawings, material preferences, and specific requirements. Our team will assess them and provide an accurate and competitive quote based on materials, processes, and market conditions.

Q: What is your minimum order quantity (MOQ)?

A: For small products, our MOQ is 100 pieces. For larger products, we can accommodate orders starting from 10 pieces.

Q: Can you provide necessary documents?

A: Yes, we offer comprehensive support with certificates of quality (e.g., ISO9001), insurance, certificates of origin, and other export documents as required.

Q: What is the lead time after ordering?

A:Samples: Approximately 7 days.

Mass Production: 35-40 days after payment confirmation.

Q: What payment methods do you accept?

A: We accept multiple payment methods, including Bank Transfer, Western Union, PayPal, and TT (Telegraphic Transfer).

Q: Do you offer packaging customization?

A: Yes, we can provide custom packaging options to meet your branding and shipping requirements, including logo printing and protective materials.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation