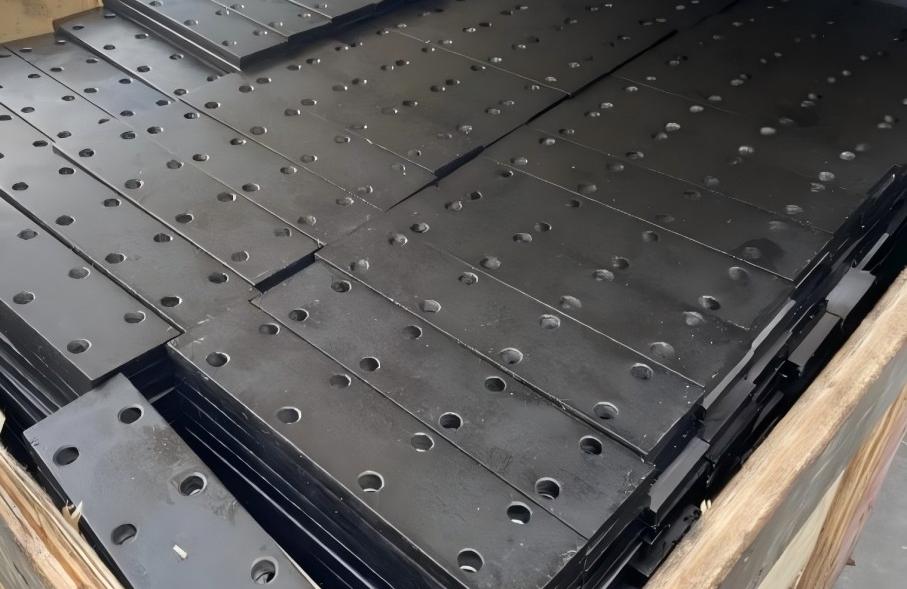

OEM Machinery Metal Slotted Shims

Description

● Product type: customized product

● Process: laser cutting

● Material: carbon steel Q235, stainless steel

● Surface treatment: galvanized

|

Model |

Length |

Width |

Slot Size |

Suitable For Bolts |

|

Type A |

50 |

50 |

16 |

M6-M15 |

|

Type B |

75 |

75 |

22 |

M14-M21 |

|

Type C |

100 |

100 |

32 |

M19-M31 |

|

Type D |

125 |

125 |

45 |

M25-M44 |

|

Type E |

150 |

150 |

50 |

M38-M49 |

|

Type F |

200 |

200 |

55 |

M35-M54 |

Dimensions in:mm

Advantages of slotted shims

Easy to install

The slotted design allows for quick insertion and removal without completely disassembling the components, saving time and effort.

Precise alignment

Provides precise gap adjustment, helps to accurately align equipment and components, and reduces wear and offset.

Durable and reliable

Made of high-quality metal materials, it is corrosion-resistant and high-temperature resistant, and can function stably for a long time.

Reduce downtime

The slotted design facilitates quick adjustment, which helps to shorten the downtime of equipment maintenance and adjustment and improve production efficiency.

A variety of thicknesses are available

A variety of thickness specifications are available to facilitate the selection of shims suitable for specific gaps and loads, and flexibly meet different needs.

Easy to carry and store

Slotted shims are small in size and light in weight, easy to carry and store, and suitable for on-site operations or emergency repairs.

Improve safety

Precise gap adjustment can enhance the stability of equipment and reduce the risk of failure due to improper alignment, thereby improving operational safety.

Versatility

These advantages make slotted shims a common tool in the industrial field, especially suitable for scenarios that require frequent adjustments and precise alignment.

Application Areas

● Construction

●Elevators

●Hose clamps

●Railroads

●Automotive parts

●Truck and trailer bodies

●Aerospace engineering

●Subway cars

●Industrial engineering

●Power and utilities

●Medical equipment components

●Oil and gas drilling equipment

●Mining equipment

●Military and defense equipment

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Professional technical team

Xinzhe has a professional team composed of senior engineers, technicians and technical workers. They have accumulated rich experience in the field of sheet metal processing and can accurately understand customer needs.

High-accuracy apparatus

It can do high-precision processing since it is outfitted with sophisticated laser cutting, CNC punching, bending, welding, and other processing tools. Make sure the product satisfies the high standards set by the clients for product quality by checking its dimensions and shape.

manufacturing efficiency

Cutting the manufacturing cycle and increasing production efficiency are possible with advanced processing equipment. It can increase customer satisfaction by promptly meeting delivery needs.

Diversified processing capabilities

It can satisfy the various demands of various clients by using a range of different processing equipment types. Large industrial equipment housings or tiny precision sheet metal parts can both be treated to a high degree of quality.

Continuous innovation

We constantly keep up with the most recent technical advancements and market trends, actively introduce cutting-edge processing tools and procedures, innovate and upgrade technology, and provide clients higher-caliber, more effective processing services.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q: How can I get a quote?

A: Our prices are determined by process, materials and other market factors.

After your company contacts us with drawings and required material information, we will send you the latest quotation.

Q: What is your minimum order quantity?

A: Our minimum order quantity for small products is 100 pieces and for large products is 10 pieces.

Q: How long can I wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

For mass-produced products, they will be shipped within 35-40 days after receiving the deposit.

If our delivery time is inconsistent with your expectations, please raise your objection when inquiring. We will do everything we can to meet your needs.

Q: What payment methods do you accept?

A: We accept payment via bank account, Western Union, PayPal or TT.