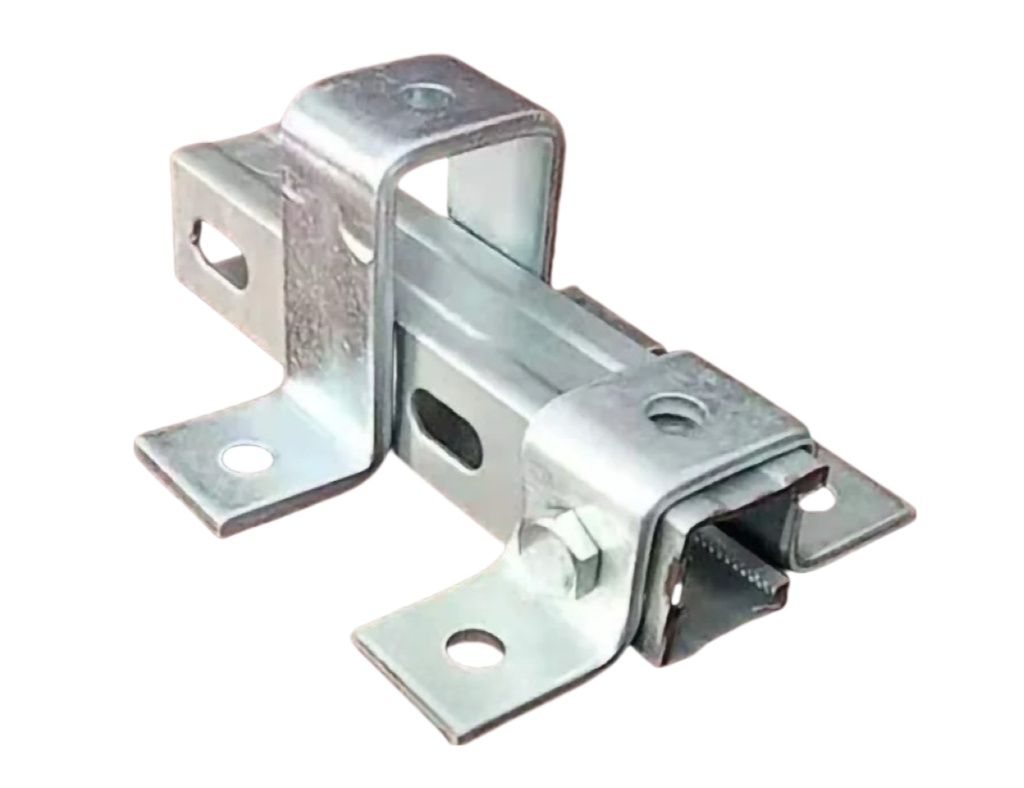

OEM galvanized U-shaped connection bracket

Description

● Length: 135 mm

● Width: 40 mm

● Height: 41 mm

● Thickness: 5 mm

● Aperture: 12.5 mm

A variety of sizes are available.

Customized production is also available based on drawings

| Product Type | Metal structural products | |||||||||||

| One-Stop Service | Mold development and design → Material selection → Sample submission → Mass production → Inspection → Surface treatment | |||||||||||

| Process | Laser cutting → Punching → Bending | |||||||||||

| Materials | Q235 steel, Q345 steel, Q390 steel, Q420 steel,304 stainless steel, 316 stainless steel,6061 aluminum alloy, 7075 aluminum alloy. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Building beam structure, Building pillar, Building truss, Bridge support structure, Bridge railing, Bridge handrail, Roof frame, Balcony railing, Elevator shaft, Elevator component structure, Mechanical equipment foundation frame, Support structure, Industrial pipeline installation, Electrical equipment installation, Distribution box, Distribution cabinet, Cable tray, Communication tower construction, Communication base station construction, Power facility construction, Substation frame, Petrochemical pipeline installation, Petrochemical reactor installation, etc. | |||||||||||

Advantages of U-shaped Connection Bracket

Simple Structure

The structural design of the U-shaped connection bracket is simple and clear, which is very convenient and quick during installation and use. No complex tools or skills are required.

Strong Load-bearing Capacity

Despite its simple design, the U-shaped connection bracket performs very well in bearing weight and tension, and can ensure that the line or pipeline is not easy to move or loosen when subjected to external forces.

Wide Application

The U-shaped connection bracket can be widely used in many fields, including but not limited to the construction industry, mechanical engineering, transportation, etc., and has become an indispensable connector in many projects and projects.

Production process

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Quality Inspection

Our Advantages

Stringent methodology for quality inspection

Xinzhe has set up a comprehensive quality control system, complete with personnel and equipment for professional inspections. Strict testing and inspections are carried out on raw materials, semi-finished goods, and final goods. Make sure the goods satisfy all applicable standards and client requirements, including those related to dimensional accuracy, surface quality, and mechanical attributes.

Superior source of raw materials

Superior raw materials serve as the foundation for guaranteeing product quality and can mitigate the likelihood of quality issues in the final product. We build enduring working partnerships with reputable raw material suppliers to guarantee that the raw materials—such as pipes and metal sheets—are of consistent quality and stable performance.

Continuous quality improvement

We focus on analyzing and summarizing quality problems in the production process, continuously improving production processes and management methods, and improving product quality stability and consistency. Through continuous quality improvement, we can improve customer satisfaction and trust.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q: Is your laser cutting equipment imported?

A: We have advanced laser cutting equipment, some of which are imported high-end equipment.

Q:How accurate is it?

A:Our laser cutting precision can attain an extremely high degree, with errors often occurring within ±0.05mm.

Q:How thick of a sheet of metal can be cut?

A: It is capable of cutting metal sheets with varying thicknesses, ranging from paper-thin to several tens of millimeters thick. The kind of material and the equipment model determine the precise thickness range that can be cut.

Q: After laser cutting, how is the edge quality?

A: There is no need for further processing because the edges are burr-free and smooth after cutting. It is highly guaranteed that the edges are both vertical and flat.