Advantages of hybrid manufacturing

In the field of modern sheet metal manufacturing, the application of hybrid manufacturing technology is increasing, becoming a popular development trend. Hybrid manufacturing combines traditional high-precision processing technology with advanced additive manufacturing (3D printing) technology, with significant advantages.

Hybrid manufacturing greatly enhances the flexibility of design. Designers are no longer restricted by traditional processes and can innovate boldly. Whether it is a unique appearance structure or a complex internal cavity, it can be easily realized, effectively meeting the diverse needs of customers.

Practice of hybrid manufacturing in sheet metal processing industry

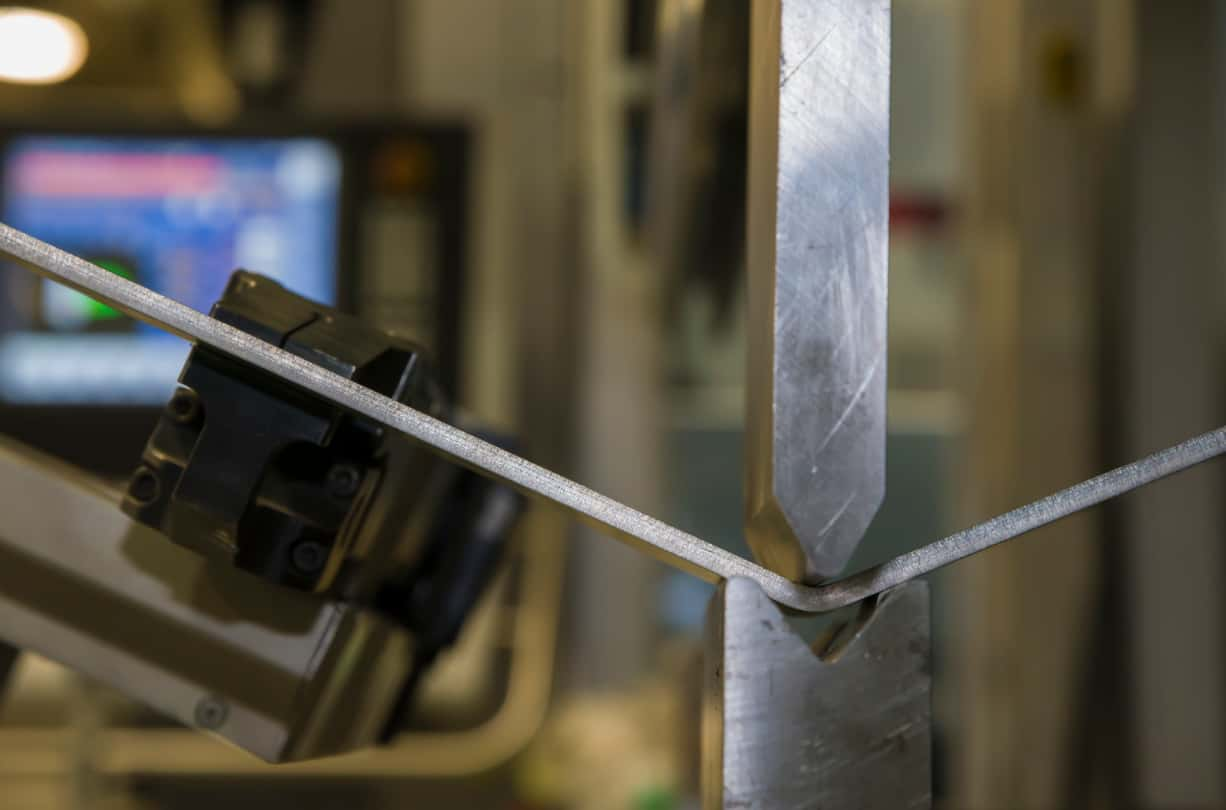

In the manufacturing of large electronic equipment brackets, such as servers and computers, traditional metal processing processes such as welding and bending can be integrated with CNC processing technology. Welding and bending quickly create the basic frame of the bracket, and CNC processing achieves high-precision hole processing and complex shape cutting to meet the needs of equipment installation and heat dissipation. At the same time, surface treatment technologies such as spraying and anodizing are used to improve the corrosion resistance and appearance quality of the bracket.

For industrial equipment brackets and mechanical equipment supports, hybrid manufacturing combines traditional processes such as casting and forging with CNC processing technology. Casting and forging produce high-strength bracket blanks, and CNC processing performs precise size adjustment and hole processing to meet installation requirements. Surface treatment technologies such as heat treatment and shot peening can also be used to improve the strength and wear resistance of the bracket.

In terms of pipeline support brackets, hybrid manufacturing combines welding, bolt connection and other processes with prefabricated parts to quickly assemble the bracket structure, and prefabricated parts improve production efficiency and quality stability.

Quality and future

In terms of quality, hybrid manufacturing has obvious advantages. Advanced manufacturing technology brings higher precision and better surface quality, reducing the workload of subsequent processing. The combination of multiple materials meets different performance requirements and improves the overall quality of the product. Through the precise additive manufacturing process, material waste is reduced, costs are saved, and product dimensional accuracy and shape accuracy are guaranteed. The efficient production brought by advanced equipment shortens the delivery cycle and better meets customer needs.

With the increasing demand for high precision, customization and high efficiency in the sheet metal processing industry, the application prospects of hybrid manufacturing are very broad. Many manufacturing companies have begun to put it into use in order to gain an advantage in future competition. For the sheet metal processing field, hybrid manufacturing is not only a technological innovation, but also a new chapter in efficient and customized production.

Post time: Oct-08-2024