In high-performance engines, turbochargers and wastegate brackets are key components. A suitable turbo wastegate bracket not only ensures the stability and efficiency of the turbocharger, but also provides reliable support during long-term high-load operation. Let me provide you with references on how to choose the right turbo wastegate bracket.

Why Choosing the Right Turbo Wastegate Bracket Matters

The main function of the turbine wastegate bracket is to support and fix the position of the wastegate in the turbocharger system to ensure its stable operation. An inappropriate bracket may cause the wastegate to not work properly, thus affecting the performance and efficiency of the turbocharger.

● Improve stability: A suitable bracket can ensure that the wastegate does not move at high speeds, avoiding engine performance degradation.

● Improve response speed: The stability of the bracket directly affects the response speed of the wastegate, which in turn affects the overall performance of the turbocharger.

● Reduce wear: A high-quality bracket can reduce friction and wear, and extend the service life of the wastegate and other turbo components.

Step 1: Understand Your Engine Requirements

Understanding your engine type and the features of the turbocharger system is essential before selecting a turbine wastegate bracket because every engine has different needs.

● Racing engine: Because it must endure greater strains and temperatures, it requires more bracket material, typically aluminum alloy or stainless steel that can survive high temperatures.

● Industrial engines: High-strength metals such forged steel are appropriate for the bracket's corrosion resistance and strength, which are essential for long-term high-load operation.

● Cars or performance cars: Usually need to be customized according to the size of the turbine to ensure that the exhaust valve can still run smoothly after modification.

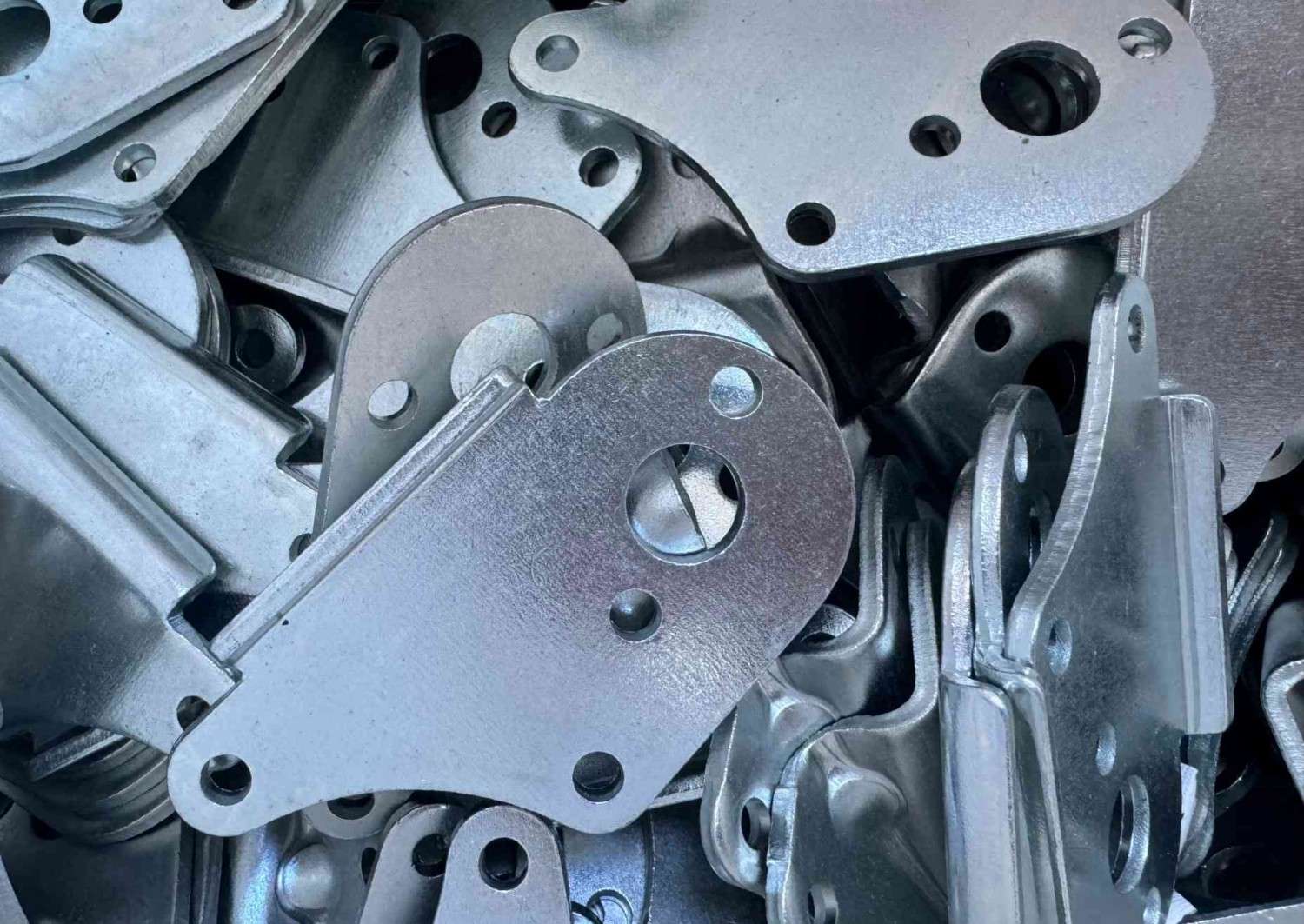

Step 2: Select the Right Material

● Stainless steel: With excellent high temperature resistance and corrosion resistance, suitable for high-performance racing cars and high-temperature environments.

● Aluminum alloy: Lightweight and durable, suitable for modified cars and light engines with weight requirements.

● Forged steel: Suitable for heavy industrial equipment, can withstand extreme loads and high-temperature working environments.

Step 3: Determine the correct size and fit

The accuracy of the size and mounting hole position directly affects the stability and performance of the exhaust valve.

The hole diameter is selected according to the size of the exhaust valve and the bolt specifications.

The bracket length and width should match the position of the turbocharger and exhaust valve to avoid improper installation affecting the use effect.

Step 4: Confirm Durability and Quality

Make sure the turbine exhaust valve bracket you choose has undergone extensive quality testing and is capable of withstanding the engine's high temperatures, vibrations, and loads. To guarantee that every bracket satisfies strict quality standards, Xinzhe's brackets are produced using an ISO 9001 certified quality system.

Step 5: Advice for Installation and Upkeep

The bracket's and other turbine components' service lives can be increased with proper installation and consistent maintenance.

Installation Advice: To prevent wear or looseness, make sure the exhaust valve and bracket are securely fastened.

Regular Inspection: Examine the exhaust valve and bracket wear on a regular basis, and repair any broken components as soon as possible.

Post time: Nov-06-2024