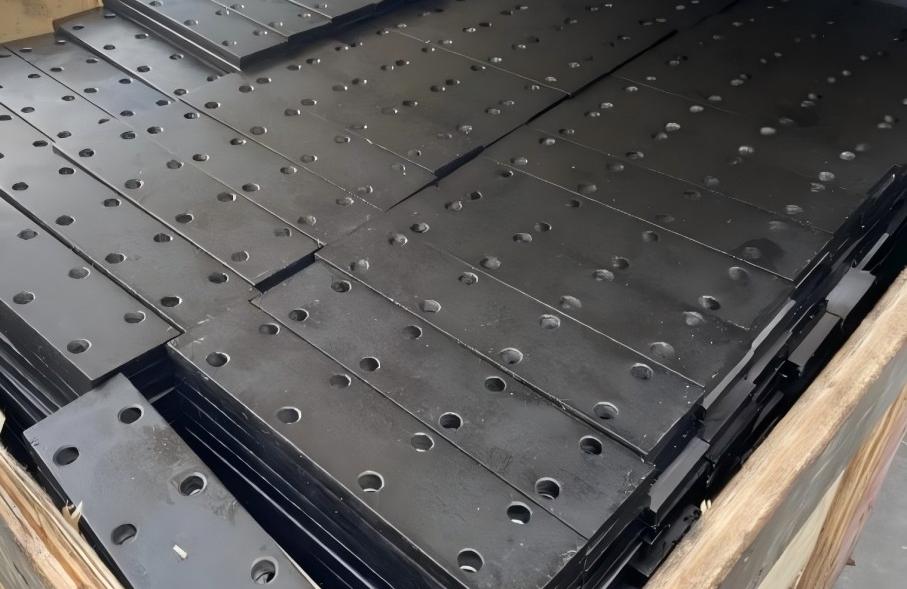

Laser cutting galvanized square embedded steel plates for buildings

Description

● Length: 115 mm

● Width: 115 mm

● Thickness: 5 mm

● Hole spacing length: 40 mm

● Hole spacing width: 14 mm

Customization is available upon request.

| Product Type | Customized Products | |||||||||||

| One-Stop Service | Mold development and design-Material selection-Sample submission-Mass production-Inspection-Surface treatment | |||||||||||

| Process | Laser cutting-Punching-Bending-Welding | |||||||||||

| Materials | Q235 steel, Q345 steel, Q390 steel, Q420 steel,304 stainless steel, 316 stainless steel,6061 aluminum alloy, 7075 aluminum alloy. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Building beam structure, Building pillar, Building truss, Bridge support structure, Bridge railing, Bridge handrail, Roof frame, Balcony railing, Elevator shaft, Elevator component structure, Mechanical equipment foundation frame, Support structure, Industrial pipeline installation, Electrical equipment installation, Distribution box, Distribution cabinet, Cable tray, Communication tower construction, Communication base station construction, Power facility construction, Substation frame, Petrochemical pipeline installation, Petrochemical reactor installation, Solar energy equipment,etc. | |||||||||||

Advantages

●High cost performance

●Easy installation

●High bearing capacity

●Strong corrosion resistance

●Good stability

●High cost-effectiveness

●Wide application range

Why use galvanized embedded plates?

1. Ensure the firmness of the connection

Embedded in concrete to form a firm fulcrum: The embedded plate is fixed in the concrete through anchors or directly, and forms a strong support point after the concrete solidifies. Compared with drilling holes or adding support parts later, the embedded plate can withstand greater tension and shear force.

Avoid loosening and offset: Since the embedded plate is fixed when pouring concrete, it will not loosen due to vibration and external force like the connectors added later, thus better ensuring the stability of the steel structure.

2. Facilitate the installation of steel components

By eliminating the need for repeated measurements and positioning during construction, steel beams, brackets, and other steel components can be directly welded or fastened to the embedding plate by bolts, improving construction efficiency and reducing labor and time expenses.

In order to minimize any potential effects on the structural strength, no holes need to be drilled in the poured concrete while installing the steel structure because the embedding plate has designated connection holes or welding surfaces per the design drawings.

3. Adapt to high stress and specific force requirements

Disperse load: In key parts of bridges and buildings, embedded plates can help disperse structural loads, transfer loads evenly to concrete structures, reduce local stress concentration, and prevent steel structure components from breaking due to excessive stress.

Provide pull-out and shear resistance: embedded plates are usually used with anchors to resist high pull-out and shear forces, which is particularly important in high-stress environments such as multi-story buildings, bridges, and equipment bases.

4. Adapt to complex structural design

Flexible application to complex and irregular structures: The thickness and shape of the embedded plate can be precisely combined with the complex structure and can be flexibly adjusted to meet the design specifications. For example, in structures such as equipment platforms and pipeline supports, the embedded plate can be precisely positioned as needed to make the components seamlessly connected.

5. Improve the overall durability of the project

Reduce rust and maintenance needs: The embedded plate is covered with concrete and galvanized, so there are few locations exposed to corrosive environments. With this double protection, the service life of the project is greatly extended and the frequency of structural maintenance is reduced.

Ensure construction site safety: The firmness of the embedded plate ensures the stability and safety of steel structure installation, especially in high-altitude operations or large equipment installation. It can greatly reduce the possibility of construction-related accidents.

The role of the embedded galvanized embedded plate in the steel structure project is very critical. It is not only a connector, but also the support and guarantee of the entire structure. It plays an irreplaceable role in terms of installation convenience, force performance, durability and safety.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Our service areas cover a wide range of industries including construction, elevators, bridges, automobiles, mechanical equipment, solar energy, etc. We provide customers with customized solutions for a variety of materials such as stainless steel, carbon steel, aluminum alloy, etc. The company has ISO9001 certification and strictly controls product quality to meet international standards. With advanced equipment and rich experience in sheet metal processing, we meet customers' needs in steel structure connectors, equipment connection plates, metal brackets, etc. We are committed to going global and working with global manufacturers to help bridge construction and other large projects.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q:How to get a quote?

A:Our prices will vary according to market factors such as process and materials.

After your company contacts us to obtain and provide drawings and material information, we will send you the latest quotation.

Q:What is your minimum order quantity?

A:The minimum order quantity for our small products is 100 pieces, and the minimum order quantity for large products is 10 pieces.

Q:How long will it take to ship after placing an order?

A:The sample delivery time is about 7 days after payment.

The mass production product delivery time is 35-40 days after receiving the payment.