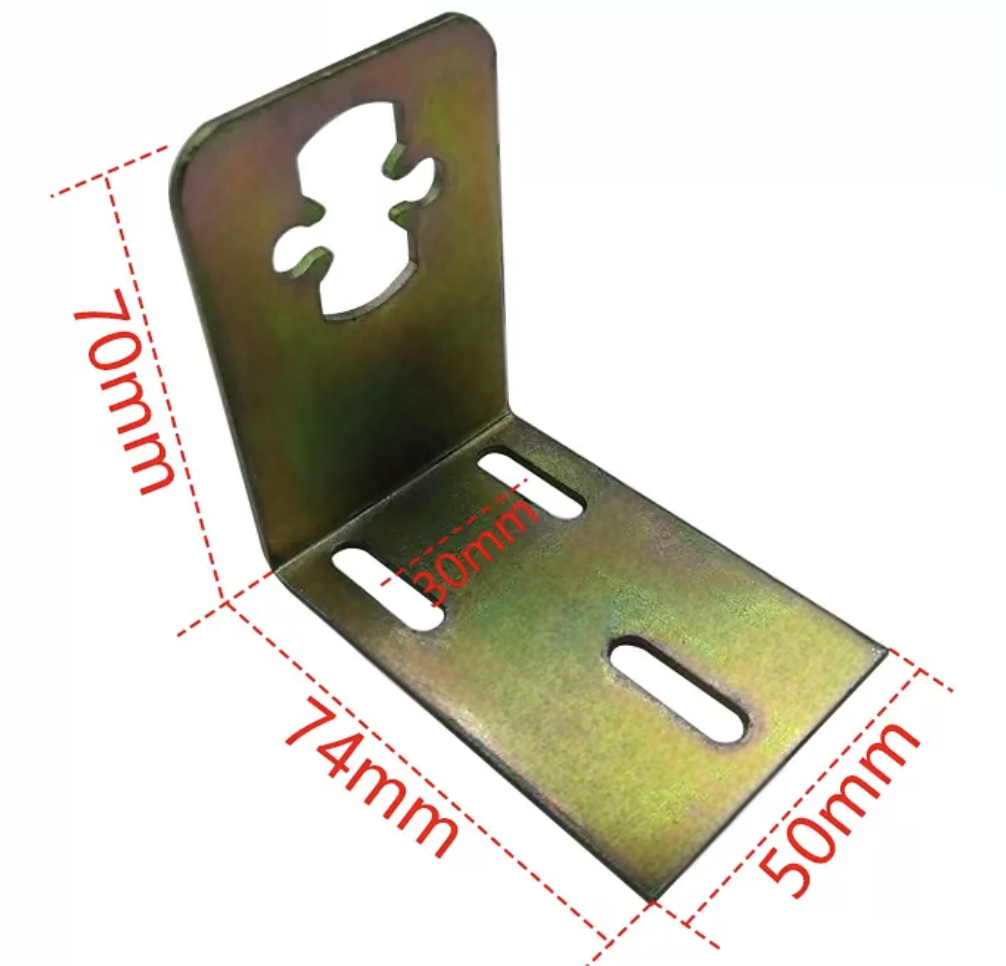

High strength bending bracket elevator speed limit switch bracket

● Length: 74 mm

● Width: 50 mm

● Height: 70 mm

● Thickness: 1.5 mm

● Material: Carbon steel, stainless steel

● Processing: Cutting, bending, punching

● Surface treatment: galvanized

Dimensions are for reference only

Product Advantages

Sturdy structure: Made of high-strength steel, it has excellent load-bearing capacity and can withstand the weight of elevator doors and the pressure of daily use for a long time.

Precise fit: After precise design, they can perfectly match various elevator door frames, simplify the installation process and reduce commissioning time.

Anti-corrosion treatment: The surface is specially treated after production, which has corrosion and wear resistance, suitable for various environments, and prolongs the service life of the product.

Diverse sizes: Custom sizes can be provided according to different elevator models.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in construction, elevators, bridges, electricity, auto parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-shaped groove brackets, angle steel brackets, galvanized embedded base plates, elevator mounting brackets, turbine housing clamp plate, Turbo wastegate bracket and fasteners, etc., which can meet the diverse project needs of various industries.

As a sheet metal processing facility with ISO9001 certification, we collaborate closely with numerous foreign manufacturers of construction, elevator, and machinery to offer them the most affordable, tailored solutions.

Realizing the goal of "delivering our products and services to every corner of the world and jointly shaping the global future" will require us to keep innovating, upholding high standards of quality, and collaborating with clients worldwide to develop more sustainable and effective solutions, connect the world with top-notch goods and services, and make quality and trust our global business card.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

What are the risks if the limit switch bracket is used improperly?

1. Inaccurate installation

Limit switches need to be installed precisely at specific locations on the equipment to ensure that they work properly. Without the support of the bracket, the switch may be installed unstable or positional deviation, causing it to fail to trigger accurately, thus affecting the control system of the equipment. The safety and accuracy of the equipment will be greatly reduced.

2. Increased safety risks

Limit switches are used to prevent equipment from operating beyond the predetermined range to avoid collisions, overloads or other failures. If the limit switch does not work correctly, the equipment may continue to operate to a dangerous position, causing damage, equipment shutdown or operator injury. This is particularly dangerous for elevators, industrial equipment, automation systems and other use occasions, and directly affects safety.

3. Equipment failure and damage

Limit switches without stable support are susceptible to external vibration, collision or environmental changes, causing their function to fail or be damaged. For example, elevator doors may open and close excessively without accurate limit, causing mechanical or electrical failures in the elevator system. In the long run, this failure may cause large-scale equipment shutdown, not only increasing maintenance costs, but also possible safety accidents.

4. Difficult maintenance and adjustment

The lack of a bracket to hold the switch means that every time you adjust, repair or replace the limit switch, it requires more laborious installation and positioning. The lack of standardized support positions may lead to misoperation or extended installation time, which will affect the normal operation of the equipment.

5. Shortened service life

If the limit switch is not adequately supported, it may be damaged prematurely due to vibration, collision or long-term wear. Without a specially designed bracket to reduce these effects, the service life of the switch may be greatly shortened, increasing the cost of replacement and repair.

6. Compatibility and adaptation issues

Limit switch brackets are usually customized according to different equipment and switch types. Not using a bracket may cause the limit switch to be incompatible with other parts of the equipment, which in turn affects the operation of the overall system.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation