High quality galvanized limit switch universal mounting brackets

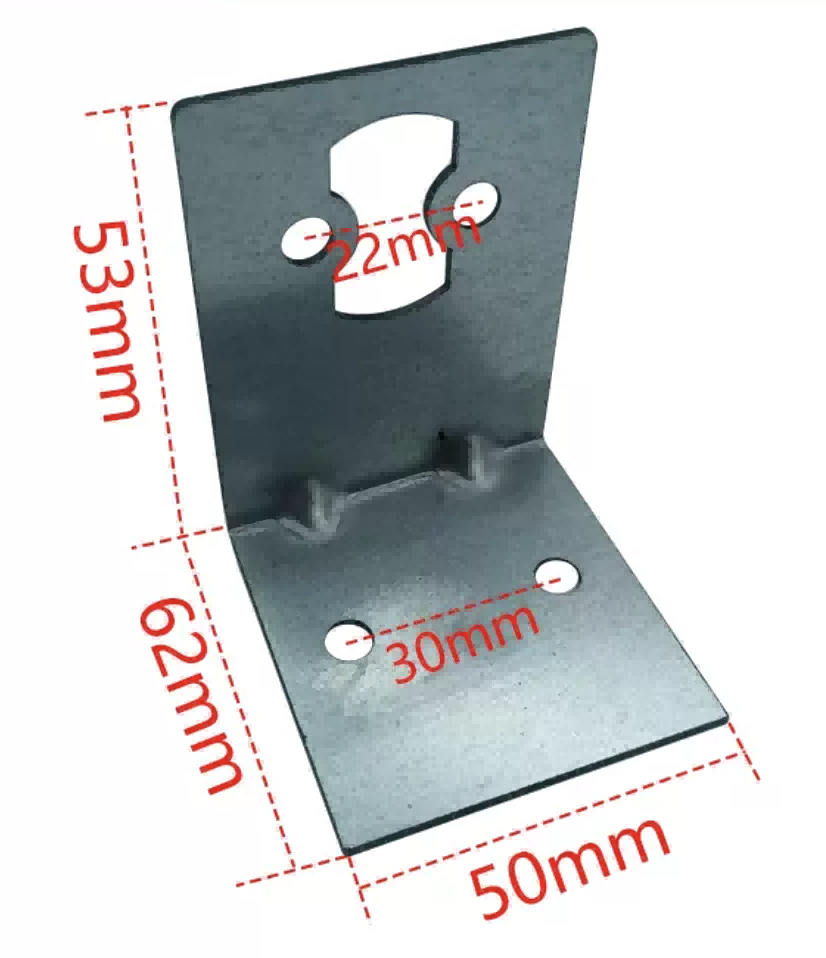

● Length: 62 mm

● Width: 50 mm

● Height: 53 mm

● Thickness: 1.5 mm

● Hole spacing: 30 mm

● Material: stainless steel, carbon steel

● Process: shearing, bending

● Surface treatment: galvanized

Dimensions are for reference only

Our Advantages

Precision machining technology

Laser cutting and CNC stamping technology are used to ensure high dimensional accuracy, smooth edges without burrs, and smoother installation.

Provide highly consistent finished products, suitable for mass production and meet strict technical requirements.

Surface treatment process

The galvanizing process enhances corrosion resistance and effectively extends the service life of the bracket in humid or high temperature environments.

The surface is smooth and beautiful, with strong wear resistance, avoiding wear problems during switch operation.

Welding and bending technology

Precision bending is used to ensure the structural strength and stability of the bracket and ensure the accurate installation angle of the limit switch.

Automated welding technology is used when necessary to enhance the strength of the bracket while ensuring a neat appearance.

Customization capability

Supports non-standard customization, adjusts the shape, size and material according to customer needs, and adapts to the use of various special scenarios.

Specific processes such as spraying and electrophoresis can be added to improve the performance and aesthetics of the bracket.

Strict quality control

The ISO 9001 quality management system runs through the process to ensure that each product meets high quality requirements.

Each bracket undergoes strict load testing and durability inspections to provide reliable process guarantees.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in construction, elevators, bridges, electricity, auto parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-shaped groove brackets, angle steel brackets, galvanized embedded base plates, elevator mounting brackets, turbine housing clamp plate, Turbo wastegate bracket and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment, combined with production processes such as bending, welding, stamping, and surface treatment to ensure the accuracy and service life of the products.

As an ISO9001 certified sheet metal processing factory, we work closely with many international machinery, elevator and construction equipment manufacturers to provide them with the most competitive customized solutions.

In order to realize the vision of "delivering our products and services to every corner of the world and jointly shaping the global future", we will continue to innovate, adhere to high quality standards, and work hand in hand with global customers to create more efficient and sustainable solutions, connect the world with excellent products and services, and make trust and quality our global business card.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How can I obtain a quote?

A: We will provide you the most competitive price as soon as possible if you simply submit us your drawings and necessary supplies via WhatsApp or email.

Q: What is the smallest order quantity that you accept?

A: Our small products require a minimum order number of 100 pieces, while our large products require a minimum order quantity of 10 pieces.

Q: How long do I have to wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

Mass production products are 35 to 40 days after payment.

Q: How do you make payments?

A: You can pay us using PayPal, Western Union, bank accounts, or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation