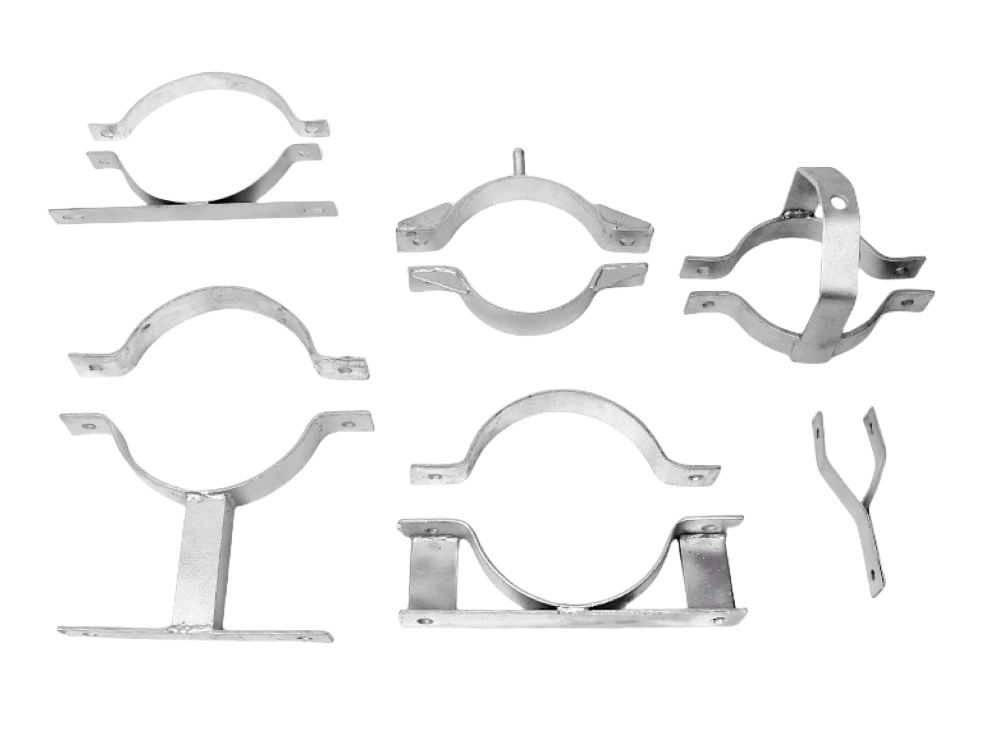

Galvanized steel pipe clamps for building installations

● Length: 147 mm

● Width: 147 mm

● Thickness: 7.7 mm

● Hole diameter: 13.5 mm

Can be customized on request

| Product Type | Metal structural products | |||||||||||

| One-Stop Service | Mold development and design → Material selection → Sample submission → Mass production → Inspection → Surface treatment | |||||||||||

| Process | Laser cutting → Punching → Bending | |||||||||||

| Materials | Q235 steel, Q345 steel, Q390 steel, Q420 steel,304 stainless steel, 316 stainless steel,6061 aluminum alloy, 7075 aluminum alloy. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Building beam structure, Building pillar, Building truss, Bridge support structure, Bridge railing, Bridge handrail, Roof frame, Balcony railing, Elevator shaft, Elevator component structure, Mechanical equipment foundation frame, Support structure, Industrial pipeline installation, Electrical equipment installation, Distribution box, Distribution cabinet, Cable tray, Communication tower construction, Communication base station construction, Power facility construction, Substation frame, Petrochemical pipeline installation, Petrochemical reactor installation, etc. | |||||||||||

Function of steel pipe clamps

Fix the position of the pipeline to guarantee the stability of the pipeline system and to stop it from moving while in operation.

Carry the pipeline's weight,shift the pipeline's weight to the supporting structure to relieve strain on the pipeline's connecting section.

Minimize pipeline vibration by absorbing its vibrations and impacts, as well as minimizing the noise it makes while operating and its effects on the nearby structures.

varieties of pipe clamps

By material:

Metal clamps: such as steel clamps, high strength, good durability, suitable for various industrial pipes.

Plastic clamps: light weight, corrosion resistance, easy installation, commonly used in water supply and drainage pipes, etc.

By shape:

U-shaped clamps: U-shaped, fastened by bolts or nuts, suitable for circular pipes.

Annular clamps: It is an entire ring structure. Before joining, it must be disassembled and placed on the pipe. It works well with larger diameter pipes.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Common installation methods for pipe clamps

First, determine the installation location of the pipe and the specifications and models of the pipe clamps, and prepare the necessary tools and materials, such as wrenches, bolts, nuts, gaskets, etc.

Secondly, place the pipe clamp on the pipe and adjust the position so that the pipe clamp fits tightly with the pipe. Then use bolts or nuts to tighten the pipe clamp. Pay attention to the moderate tightening force, which should ensure that the clamp firmly fixes the pipe, but not too tight to cause damage to the pipe.

Finally, after the installation is completed, check whether the clamp is firmly installed and whether the pipe is loose or displaced. If there is any problem, adjust and repair it in time.

When installing and maintaining the pipe clamp, pay attention to safety to avoid accidents.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q: Is your laser cutting equipment imported?

A: We have advanced laser cutting equipment, some of which are imported high-end equipment.

Q:How accurate is it?

A:Our laser cutting precision can attain an extremely high degree, with errors often occurring within ±0.05mm.

Q:How thick of a sheet of metal can be cut?

A: It is capable of cutting metal sheets with varying thicknesses, ranging from paper-thin to several tens of millimeters thick. The kind of material and the equipment model determine the precise thickness range that can be cut.

Q: After laser cutting, how is the edge quality?

A: There is no need for further processing because the edges are burr-free and smooth after cutting. It is highly guaranteed that the edges are both vertical and flat.