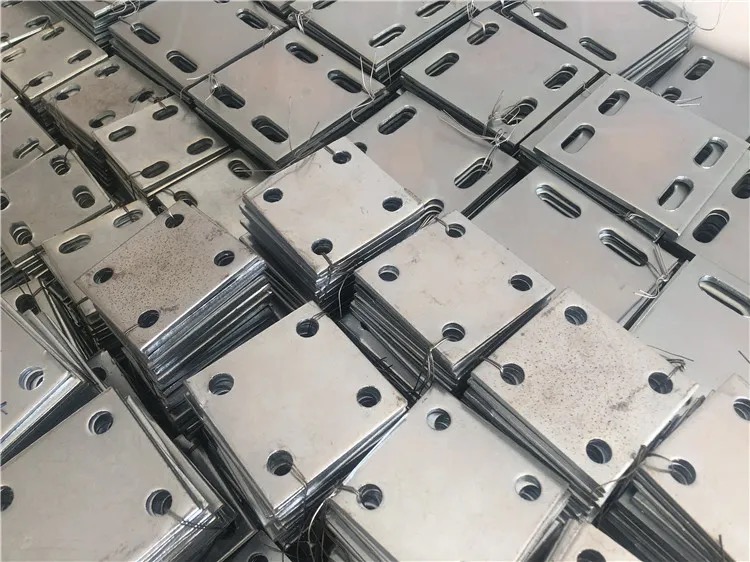

Galvanized square embedded plates for building

Description

● Length: 147 mm

● Width: 147 mm

● Thickness: 7.7 mm

● Hole diameter: 13.5 mm

Can be customized on request

| Product Type | Metal structural products | |||||||||||

| One-Stop Service | Mold development and design → Material selection → Sample submission → Mass production → Inspection → Surface treatment | |||||||||||

| Process | Laser cutting → Punching → Bending | |||||||||||

| Materials | Q235 steel, Q345 steel, Q390 steel, Q420 steel,304 stainless steel, 316 stainless steel,6061 aluminum alloy, 7075 aluminum alloy. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Building beam structure, Building pillar, Building truss, Bridge support structure, Bridge railing, Bridge handrail, Roof frame, Balcony railing, Elevator shaft, Elevator component structure, Mechanical equipment foundation frame, Support structure, Industrial pipeline installation, Electrical equipment installation, Distribution box, Distribution cabinet, Cable tray, Communication tower construction, Communication base station construction, Power facility construction, Substation frame, Petrochemical pipeline installation, Petrochemical reactor installation, etc. | |||||||||||

Why use embedded plates?

1. Reinforce the structural relationship

The embedded plate serves as a fixing element by being inserted into the concrete and fastened with steel bars or other elements, strengthening and securing the connection between the structures.

2. Boost the capacity of bearings

The Rectangular base plate can distribute the load pressure, increase the foundation's and the structure's bearing capacity, and ultimately strengthen the entire structure by offering more support surfaces.

3. Quicken the building process

When the embedded plate is positioned beforehand during the concrete pour, it can be directly fixed to by other components, saving time on drilling and welding and streamlining the building process overall.

4. Verify precise placement

Prior to pouring, the Galvanized embedded base plate's position is precisely measured and locked, preventing deviations that could compromise the structure's quality and ensuring precise location for the installation that follows.

5. Adjust for varied installation requirements

The embedding plate's size, form, and hole placement can be altered to better suit a variety of installation requirements, including those of mechanical equipment foundations, bridge supports, and diverse building structures, while also increasing application versatility.

6. Sturdiness and corrosion resistance

High-quality embedded plates often offer exceptional corrosion resistance and durability, making them ideal for long-term usage in a variety of environmental settings with little maintenance needs.

Production process

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Quality Inspection

Our Advantages

High-quality raw materials

Strict supplier screening

Establish long-term cooperative relationships with high-quality raw material suppliers, and strictly screen and test raw materials. Ensure that the quality of the metal materials used is stable and reliable, in line with international standards and customer requirements.

Diverse material selection

Provide a variety of different types of metal materials for customers to choose from, such as stainless steel, aluminum alloy, cold-rolled steel, hot-rolled steel, etc.

Environmentally friendly materials

Pay attention to environmental issues and actively adopt environmentally friendly metal materials and surface treatment processes. Provide customers with green and environmentally friendly products in line with the development trend of modern society.

Efficient production management system

Optimize production processes

Through continuous optimization of production processes, improve production efficiency and reduce production costs. Use advanced production management equipment to comprehensively manage and monitor production plans, material management, etc.

Lean production concept

Introduce lean production concepts to eliminate waste in the production process and improve production flexibility and response speed. Achieve just-in-time production and ensure that products are delivered on time.

Good after-sales service

Quick response

A complete after-sales service system has been established, which can respond quickly to customer feedback and problems.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q: Is your laser cutting equipment imported?

A: We have advanced laser cutting equipment, some of which are imported high-end equipment.

Q:How accurate is it?

A:Our laser cutting precision can attain an extremely high degree, with errors often occurring within ±0.05mm.

Q:How thick of a sheet of metal can be cut?

A: It is capable of cutting metal sheets with varying thicknesses, ranging from paper-thin to several tens of millimeters thick. The kind of material and the equipment model determine the precise thickness range that can be cut.

Q: After laser cutting, how is the edge quality?

A: There is no need for further processing because the edges are burr-free and smooth after cutting. It is highly guaranteed that the edges are both vertical and flat.