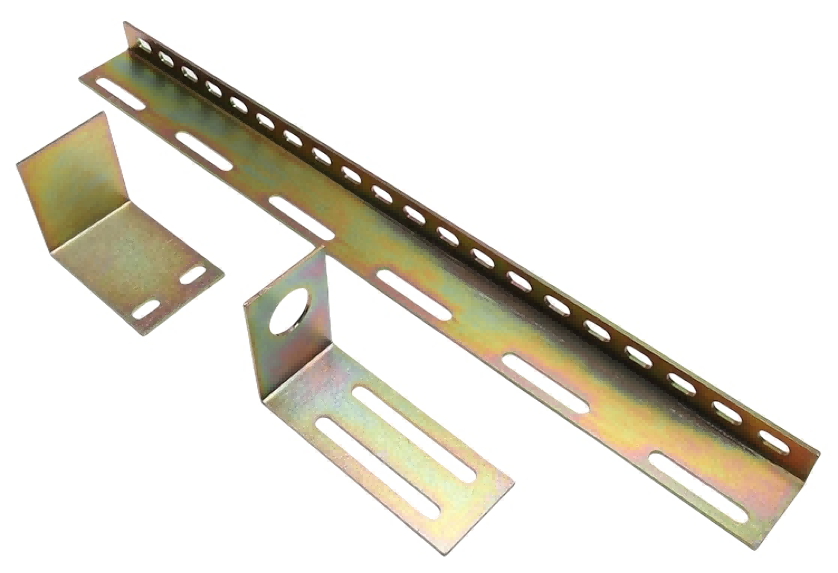

Elevator support bracket carbon steel galvanized bracket

● Length: 580 mm

● Width: 55 mm

● Height: 20 mm

● Thickness: 3 mm

● Hole length: 60 mm

● Hole width: 9 mm-12 mm

Dimensions are for reference only

●Product type: sheet metal processing products

●Material: stainless steel, carbon steel, alloy steel

●Process: laser cutting, bending

●Surface treatment: galvanizing, anodizing

●Purpose: fixing, connecting

●Weight: About 3.5 KG

Product Advantages

Sturdy structure: Made of high-strength steel, it has excellent load-bearing capacity and can withstand the weight of elevator doors and the pressure of daily use for a long time.

Precise fit: After precise design, they can perfectly match various elevator door frames, simplify the installation process and reduce commissioning time.

Anti-corrosion treatment: The surface is specially treated after production, which has corrosion and wear resistance, suitable for various environments, and prolongs the service life of the product.

Diverse sizes: Custom sizes can be provided according to different elevator models.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-channel brackets, angle brackets, galvanized embedded base plates, elevator mounting brackets and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment in conjunction with bending, welding, stamping, surface treatment, and other production processes to guarantee the precision and longevity of the products.

As an ISO 9001 certified company, we have worked closely with many international machinery, elevator and construction equipment manufacturers and provide them with the most competitive customized solutions.

According to the company's "going global" vision, we are dedicated to offering top-notch metal processing services to the global market and are constantly working to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

How to determine the load-bearing capacity of the galvanized sensor bracket?

Ensuring the load-bearing capacity of the galvanized sensor bracket is the key to safe design. The following methods combine international material standards and engineering mechanics principles and are applicable to the global market:

1. Material mechanical properties analysis

● Material strength: clarify the bracket material, such as Q235 steel (Chinese standard), ASTM A36 steel (American standard) or EN S235 (European standard).

● The yield strength of Q235 and ASTM A36 is generally 235MPa (about 34,000psi), and the tensile strength is between 370-500MPa (54,000-72,500psi).

● Galvanizing improves corrosion resistance and is suitable for long-term use.

● Thickness and size: Measure the key geometric parameters of the bracket (thickness, width, length) and calculate the theoretical load-bearing capacity through the bending strength formula σ=M/W. Here, the units of bending moment M and section modulus W need to be N·m (Newton-meter) or lbf·in (pound-inch) according to regional habits.

2. Force analysis

● Force type: The bracket may bear the following main loads during use:

● Static load: The gravity of the sensor and its related equipment.

● Dynamic load: The inertial force generated when the elevator is running, and the dynamic load coefficient is generally 1.2-1.5.

● Impact load: The instantaneous force when the elevator stops urgently or an external force acts.

● Calculate the resultant force: Combine the principles of mechanics, superimpose the forces in different directions, and calculate the total force of the bracket under the most extreme conditions. For example, if the vertical load is 500N and the dynamic load coefficient is 1.5, the total resultant force is F=500×1.5=750N.

3. Consideration of safety factor

Elevator-related brackets are part of special equipment and usually require a higher safety factor:

● Standard recommendation: The safety factor is 2-3, taking into account factors such as material defects, changes in working conditions, and long-term fatigue.

● Calculation of actual load capacity: If the theoretical load capacity is 1000N and the safety factor is 2.5, the actual load capacity is 1000÷2.5=400N.

4. Experimental verification (if conditions permit)

● Static loading test: Gradually increase the load in a laboratory environment and monitor the stress and deformation of the bracket until the limit failure point.

● Global applicability: While the experimental results verify the theoretical calculations, they must comply with regional regulatory requirements, such as:

● EN 81 (European elevator standard)

● ASME A17.1 (American elevator standard)

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation