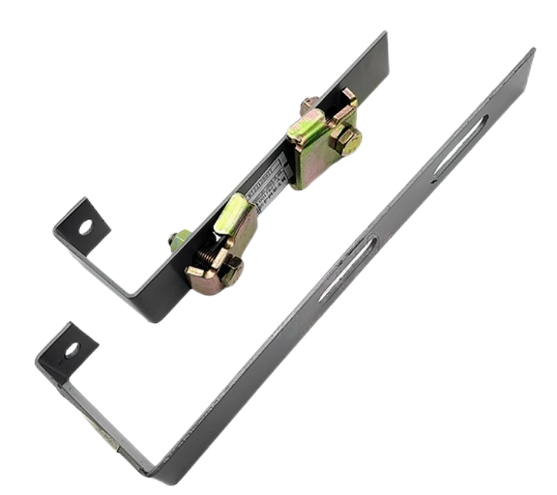

Elevator Mounting Accessories Protective Bracket Kit

● Length: 110 mm

● Width: 100 mm

● Height: 75 mm

● Thickness: 5 mm

Actual dimensions are subject to the drawing

●Product type: customized products

●Material: stainless steel, carbon steel, alloy steel

●Process: laser cutting, bending

●Surface treatment: galvanizing, anodizing

●Application: installation, maintenance and fixing of various elevators

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

What is the anodizing process?

The electrochemical process of anodizing, which is most frequently applied to aluminum and aluminum alloys, creates a protective oxide layer on the metal's surface. This procedure not only increases the material's resistance to corrosion but also improves the surface's hardness and appearance.

The fundamental anodizing procedure is as follows:

Pretreatment: To get rid of oil, oxides, and other contaminants, clean and treat the metal surface. To guarantee that the metal surface is smooth and clean, this can be accomplished by mechanical polishing or chemical cleaning.

Anodizing: The metal support is immersed in an electrolyte (usually sulfuric acid),often sulfuric acid, with the workpiece serving as the anode and a lead plate or other conductive substance serving as the cathode. A dense oxide film is created on the metal surface as a result of an oxidation reaction that happens when the current flows through.

Coloring: Dye can be absorbed by the anodized metal surface to produce a variety of hues. In order to accomplish this, dyes are introduced into the oxide layer's pores, and the color is subsequently set by sealing.

Sealing: To further increase the oxide film's resistance to corrosion, the micropores are finally sealed. Sealing is often accomplished by treating the workpiece with chemical solutions or by soaking it in hot water or steam to create hydrated aluminum oxide.

Advantages of Anodizing:

Increased resistance to corrosion: The oxide layer can successfully stop the metal surface from corroding, particularly in an acidic or humid environment.

Boost surface hardness: After anodizing, the metal's surface hardness is significantly increased, making it more resistant to wear and scratches.

Strong ornamental effect: Anodizing can provide metal surfaces a wide range of colors, making it appropriate for applications like building and electronic devices that need to have attractive surfaces.

Good adherence: The anodized surface is appropriate for further decorative treatments, such as painting, because of its good adhesion.

Good environmental protection: Less waste is produced during the anodizing process, and no hazardous metals, such chromium, are used. It is a surface treatment technique that is comparatively eco-friendly.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevators, bridges, electricity, auto parts and other industries. Our main products include fixed brackets, angle brackets, galvanized embedded base plates, elevator mounting brackets, etc., which can meet the diverse project needs.

To assure product precision and longevity, the company uses innovative laser cutting technology in conjunction with a broad range of production techniques like as bending, welding, stamping, and surface treatment.

As an ISO 9001-certified organization, we collaborate closely with numerous global construction, elevator, and mechanical equipment manufacturers to create tailored solutions.

Adhering to the corporate vision of "going global", we continue to improve product quality and service level, and are committed to providing high-quality metal processing services to the international market.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Our prices are determined by workmanship, materials and other market factors.

After your company contacts us with drawings and required material information, we will send you the latest quotation.

Q:What is the smallest order quantity that you accept?

A: Our small products require a minimum order number of 100 pieces, while our large products require a minimum order quantity of 10 pieces.

Q: After placing an order, how long must I wait for shipment?

A:1) It takes roughly seven days to send samples.

2)Products that are mass-produced will be supplied 35–40 days after the deposit is received.

When you inquire, please file an objection if our delivery time does not meet your expectations. We'll make every effort to accommodate your demands.

Q:Which forms of payment are accepted?

A: We accept payment via bank account, Western Union, PayPal or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation