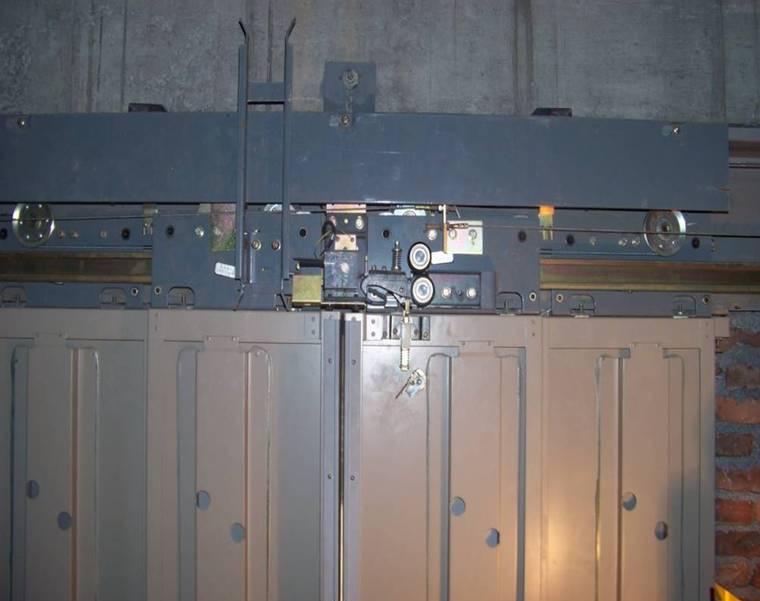

Elevator door lock plate elevator plate accessories bracket

● Length: 180 mm

● Width: 45 mm

● Height: 39 mm

● Thickness: 2 mm

● Hole length: 18 mm

● Hole width: 10 mm

Dimensions are for reference only

● Product type: elevator accessories

● Material: stainless steel, carbon steel

● Process: laser cutting, bending

● Surface treatment: galvanizing, anodizing

● Application: fixing, connecting

● Weight: about 1 KG

Product Advantages

Sturdy structure: Made of high-strength steel, it has excellent load-bearing capacity and can withstand the weight of elevator doors and the pressure of daily use for a long time.

Precise fit: After precise design, they can perfectly match various elevator door frames, simplify the installation process and reduce commissioning time.

Anti-corrosion treatment: The surface is specially treated after production, which has corrosion and wear resistance, suitable for various environments, and prolongs the service life of the product.

Diverse sizes: Custom sizes can be provided according to different elevator models.

What are the installation specifications for elevator hall door strike plates?

Installation location and size requirements

● Precise positioning: The plate should be installed on the edge of the elevator car door, at the same level and in the same position as the hall door lock device, to ensure that when the car door is opened and closed, the plate can accurately trigger the unlocking and auxiliary closing of the hall door lock.

● Size matching: Its length, width and other dimensions must match the matching dimensions of the car door and the hall door lock to ensure normal triggering and transmission functions. The general length is about 20-30 cm and the width is about 3-5 cm.

Installation horizontal and vertical requirements

● Horizontal degree: After installation, the plate must be kept horizontal, and the horizontal deviation should not exceed 0.5/1000. A level ruler can be used for measurement and adjustment to ensure the stability of the plate in the horizontal direction to avoid poor coordination with the hall door lock due to tilt.

● Verticality: The verticality deviation of the plate should not exceed 1/1000. Use plumb line and other tools to check and adjust to ensure that the relative position of the plate to the car door and hall door in the vertical direction is accurate to prevent deflection and affect the normal triggering of the door lock.

Connection and fixing requirements

● Firm and reliable: The plate should be firmly connected to the movement system of the car door, and the connecting screws should be tightened to prevent the plate from loosening, displacement or falling off during the movement of the car door. Usually, the tightening torque of the screws should meet the requirements of relevant standards.

● Connection method: Generally, screw connection or welding is used for fixing. The welding quality must be ensured during welding. The weld should be uniform and firm, without defects such as false welding and leaking welding; when screw connection is used, the screw specifications should match the connection between the plate and the car door, and anti-loosening washers should be installed.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in construction, elevators, bridges, electricity, automotive parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, u shape metal bracket, angle steel brackets, galvanized embedded base plates, elevator mounting brackets, turbine mounting brackets and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment, combined with bending, welding, stamping, surface treatment and other production processes to ensure the accuracy and service life of the products.

As an ISO9001 certified company, we work closely with many international machinery, elevator and construction equipment manufacturers to provide them with the most competitive customized solutions.

Adhering to the belief of making our brackets serve the world. We are committed to providing first-class metal processing services to the global market and constantly strive to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Just send your drawings and required materials to our email or WhatsApp, and we will provide you with the most competitive quote as soon as possible.

Q: What is your minimum order quantity?

A: The minimum order quantity for our small products is 100 pieces, and the minimum order quantity for large products is 10 pieces.

Q: How long do I have to wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

Mass production products are 35 to 40 days after payment.

Q: What is your payment method?

A: We accept payments through bank accounts, Western Union, PayPal or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation