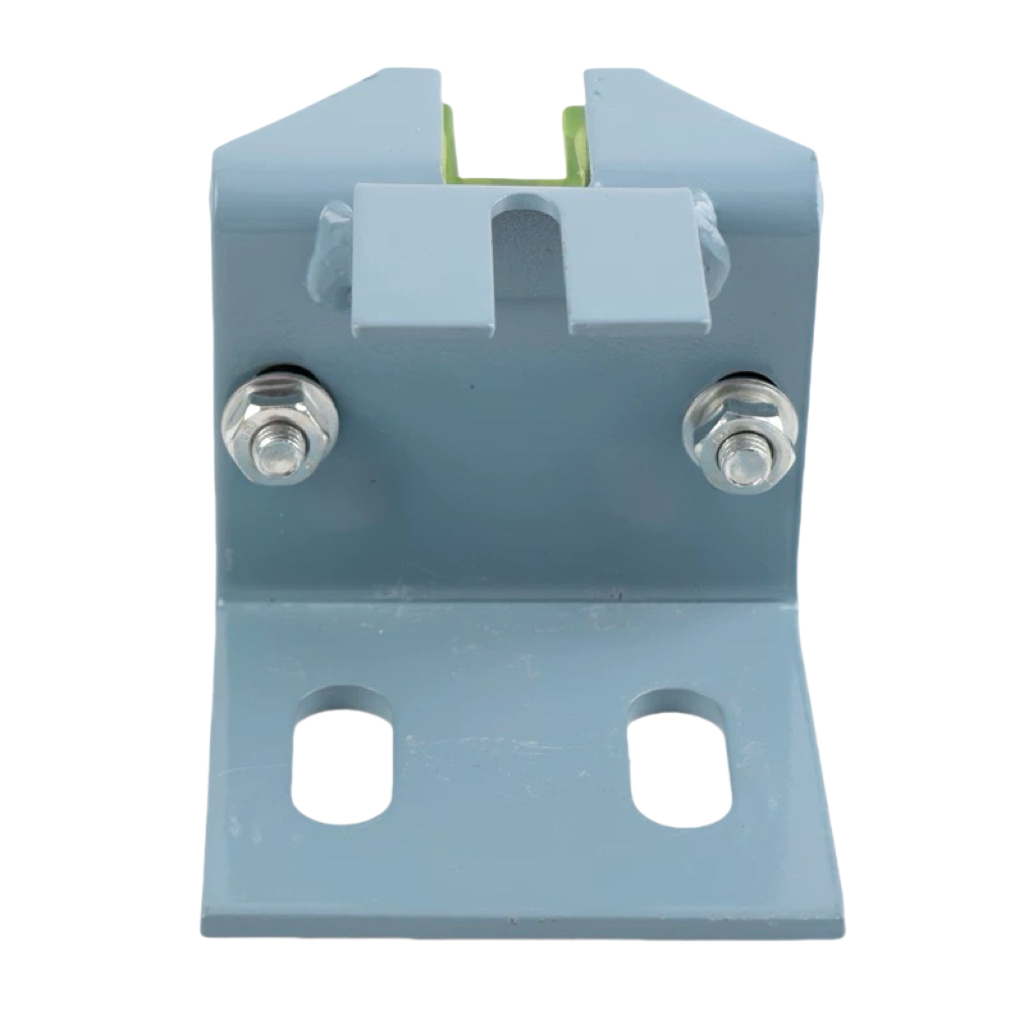

Elevator accessories guide rail guide shoe bracket

● Slot width: 19 mm

● Applicable rail: 16 mm

● Hole distance: 70 mm

● Slot width: 12 mm

● Applicable rail: 10 mm

● Hole distance: 70 mm

Technology

●Material: stainless steel, carbon steel, alloy steel

●Process: laser cutting, stamping, bending, welding

●Surface treatment: galvanizing, anodizing, spraying

●Application: fixing, supporting

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Composition of elevator guide shoe bracket

The following are often included in an elevator guide shoe bracket:

Mounting plate: utilized to secure the elevator structure's bracket.

Connecting plate: To install the guiding shoe steadily, attach the mounting plate to the guide shoe body.

The upper attaching plate:which is used to secure the guide shoe, is situated at the upper end of the guide shoe body.

Guide shoe body: installed between the connecting plates through convex blocks and convex slots to ensure the stable installation and removal of the guide shoe.

Role and Function

Maintaining and maintaining guide shoes

To avoid displacement or falling off during use, the guide shoes must be firmly fixed to the elevator car and counterweight device.

Reduce noise and vibration

By selecting appropriate structures and materials, the elevator can reduce noise and vibration and provide a more comfortable riding experience.

Improve safety

Through reasonable design and installation, ensure the stable performance of the elevator under various operating conditions, thereby reducing the possibility of failure and improving the overall safety of the elevator.

Installation and maintenance

The guide shoe bracket must be installed precisely aligned with the guide rail to ensure that the guide shoe can slide smoothly and reduce friction and vibration.

Regularly check the tightness of the bracket to ensure that all connecting parts are not loose and the bracket is free of corrosion and wear.

Properly lubricate the guide shoe and guide rail to reduce friction and extend service life.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Our prices are determined by workmanship, materials and other market factors.

After your company contacts us with drawings and required material information, we will send you the latest quotation.

Q: What is your minimum order quantity?

A: The minimum order quantity for our small products is 100 pieces, and the minimum order quantity for large products is 10 pieces.

Q: How long do I need to wait for shipment after placing an order?

A: Samples can be sent in about 7 days.

For mass-produced products, they will be shipped within 35-40 days after receiving the deposit.

If our delivery time is inconsistent with your expectations, please raise an objection when inquiring. We will do everything we can to meet your needs.

Q: What payment methods do you accept?

A: We accept payment via bank account, Western Union, PayPal or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation