Durable Elevator Landing Sill Bracket for Enhanced Stability

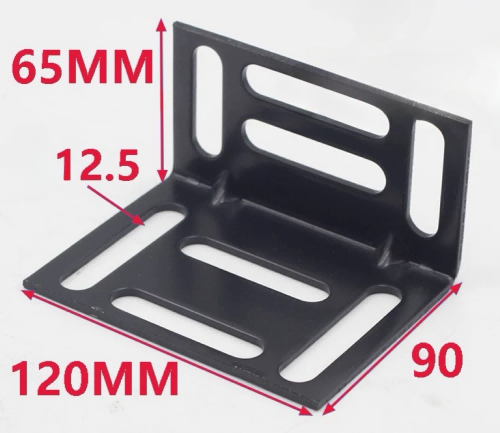

● Length: 120 mm

● Width: 90 mm

● Height: 65 mm

● Thickness: 4 mm

● Hole length: 60 mm

● Hole width: 12.5 mm

Dimensions are subject to actual drawings

● Product type: Elevator accessories

● Material: Stainless steel, Carbon steel, Alloy steel

● Process: Laser cutting, Bending

● Surface treatment: Galvanizing, Anodizing, Blackening

● Application: Fixing, Connecting

● Weight: About 4KG

Product Advantages

Accurate fit: The design may be easily integrated with guide rail systems of various brands and conforms with elevator industry requirements.

High-strength materials: To offer superior load-bearing capacity and corrosion resistance, carbon steel, stainless steel, or galvanized steel are utilized.

Flexible customization: Enables size, hole location, and surface treatment adjustments based on technical specifications to satisfy individual needs.

Several surface treatments: optional electrophoresis, painting, or galvanizing procedures to increase product protection effectiveness and prolong service life.

Simple installation: outfitted with uniform installation holes to lower mistakes and boost building productivity.

Application Areas

● High-rise residential elevator installation

● Commercial building elevator renovation

● Industrial freight elevator and heavy-duty elevator system

● Elevator engineering in high humidity and high corrosion environments

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-channel brackets, angle brackets, galvanized embedded base plates, elevator mounting brackets and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment in conjunction with bending, welding, stamping, surface treatment, and other production processes to guarantee the precision and longevity of the products.

As an ISO 9001 certified company, we have worked closely with many international machinery, elevator and construction equipment manufacturers and provide them with the most competitive customized solutions.

According to the company's "going global" vision, we are dedicated to offering top-notch metal processing services to the global market and are constantly working to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: What is the bending angle accuracy?

A: We use high-precision bending equipment and advanced bending technology, and the bending angle accuracy can be controlled within ±0.5°, which enables us to produce sheet metal products with accurate angles and regular shapes.

Q: Can complex shapes be bent?

A: Of course, our bending equipment has strong processing capabilities and can bend various complex shapes, including multi-angle bending, arc bending, etc. Our technical team can formulate the best bending plan according to the customer's design requirements.

Q: How to ensure the strength after bending?

A: During the bending process, we will reasonably adjust the bending parameters according to the characteristics of the material and the use requirements of the product to ensure that the product has sufficient strength after bending. At the same time, we will also conduct strict quality inspections to ensure that the bent parts do not have defects such as cracks and deformation.

Q: What is the maximum thickness of sheet metal that can be bent?

A: Our bending equipment can handle metal plates with a maximum thickness of 12 mm, depending on the type of material.

Q: Can the bending process be applied to stainless steel or other special materials?

A: Yes, we can bend different materials including stainless steel, aluminum and other alloys. Our equipment and process settings are tailored to each material type to maintain precise angles, surface quality and strength.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation