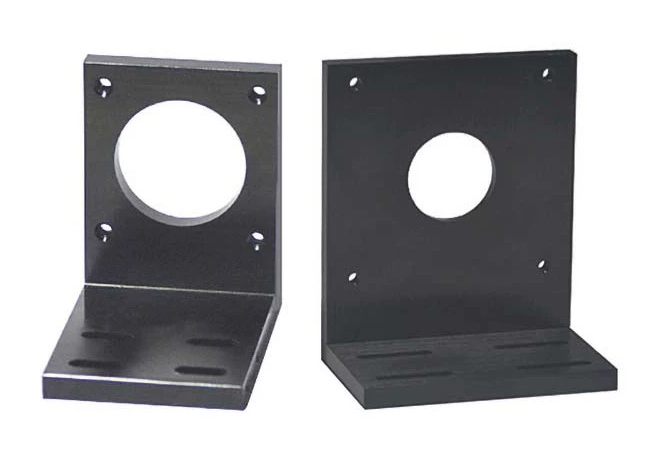

Customizable Electric Motor Support Bracket with Anti-Rust Coating

● Material: carbon steel, alloy steel, aluminum alloy

● Surface treatment: galvanized, spray-coated

● Length: 90mm

● Width: 60mm

● Height: 108mm

● Thickness: 8mm

Common types of motor brackets

Column-type motor bracket

It is a commonly used fixed motor bracket, suitable for occasions with high positioning requirements.

Sliding-type motor bracket

It is a movable motor bracket, suitable for occasions with high requirements such as packaging, printing, and woodworking.

Rotary motor bracket

It is a special movable motor bracket, suitable for occasions that require frequent direction adjustment.

What are the application areas of motor brackets?

The application areas of motor brackets are mainly the following aspects:

● Automation equipment

● Robotic arm

● Experimental equipment

● New energy vehicles

● Wind power generation

● High-tech manufacturing field

Our Advantages

Standardized production, lower unit costs

● Scaled manufacturing: Using advanced machinery and equipment, we ensure consistent product specifications and reliable performance, thereby significantly reducing unit costs.

● Efficient material utilization: Through precise cutting and advanced processing technology, material waste is minimized and cost efficiency is improved.

● Economies of scale: Large-volume production can purchase raw materials and logistics services in bulk, resulting in significant cost savings.

Factory advantages

By eliminating middlemen, we simplify the supply chain and reduce the turnover costs associated with multiple suppliers. This approach provides competitive pricing advantages for large projects.

Reliable quality through consistency

● Strict process management: We have passed ISO 9001 certification, with standardized manufacturing workflows and strict quality control systems. It ensures uniform product quality and minimizes defect rates.

● Comprehensive traceability: A strong quality traceability system can supervise the process from raw materials to finished products, ensuring stability and reliability for all bulk orders.

Tailor-made cost-effective solutions

Bulk procurement not only reduces upfront procurement expenses, but also reduces the risks associated with maintenance and rework. This approach delivers high-value, economical solutions for large projects while optimizing budgets and operational efficiencies.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Packaging and Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How can I get a quote?

A: Send us your detailed drawings and requirements, and we’ll provide an accurate and competitive quote based on materials, processes, and market conditions.

Q: What is your minimum order quantity (MOQ)?

A: 100 pieces for small products, 10 pieces for large products.

Q: Can you provide necessary documents?

A: Yes, we provide certificates, insurance, certificates of origin, and other export documents.

Q: What is the lead time after ordering?

A: Samples: ~7 days.

Mass production: 35-40 days after payment.

Q: What payment methods do you accept?

A: Bank transfer, Western Union, PayPal, and TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation