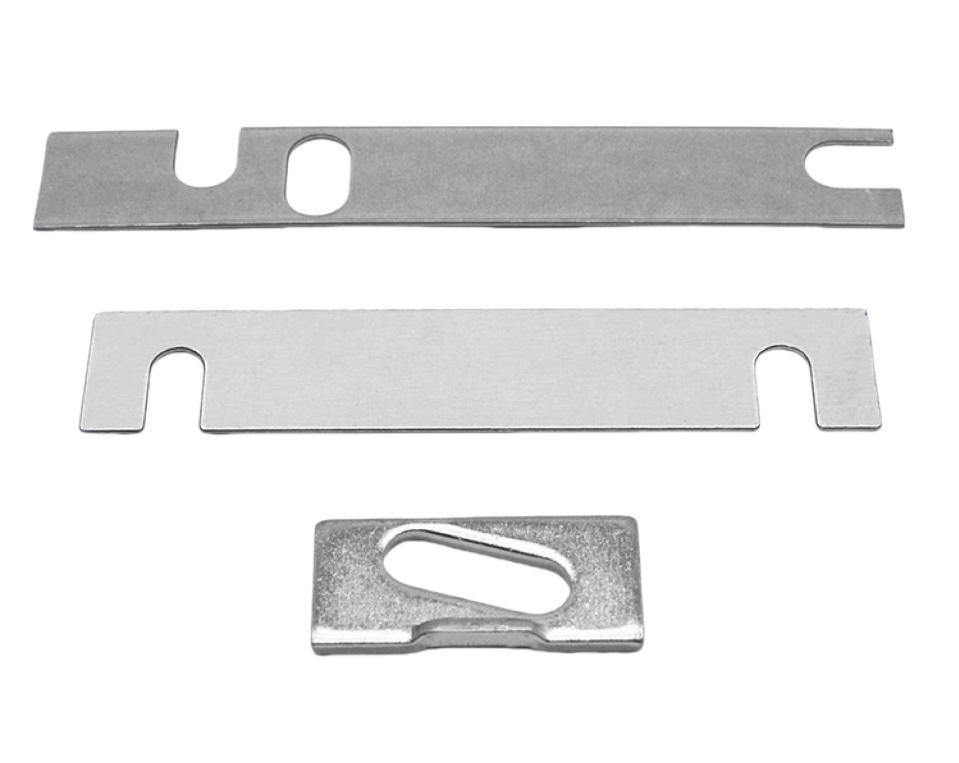

Custom laser cut slotted metal shims for elevator spare parts

Main product

● Length: 149 mm

● Width: 23 mm

● Thickness: 1.5 mm

Sub-product

● Length: 112 mm

● Width: 24 mm

● Thickness: 1.5 mm

Product Features

● Shape: Square design with slots (U-shaped, V-shaped or straight slots).

● Material: Usually made of durable metals such as stainless steel, carbon steel or aluminum alloy, some models are galvanized or coated.

● Precision: Suitable for scenarios requiring high-precision gap adjustment, the slot design facilitates installation and removal.

Functionality:

● Used for support, adjustment or fixing between connecting parts.

● Slots facilitate quick insertion into rails, bolts or other assembly parts.

Application Scenarios

1. Elevator industry

Guide rail installation: square slotted gaskets are used as adjustment parts for guide rail brackets to ensure smooth guide rail installation.

Motor or gearbox fixing: provide stable support while facilitating fine-tuning of part positions.

2. Mechanical equipment

Equipment foundation installation: used when adjusting the level or gap of the base of equipment such as machine tools and compressors.

Component assembly: used for gap adjustment between connectors, fixtures and other metal components.

3. Other projects

Applicable to gap compensation or positioning in heavy machinery, bridge installation and industrial equipment.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries.

The main products include metal building brackets, brackets galvanized, fixed brackets, U-shaped slot brackets, angle steel brackets, galvanized embedded base plates, elevator mounting brackets, turbo mounting bracket and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment, combined with bending, welding, stamping, surface treatment and other production processes to ensure the accuracy and service life of the products.

Being an ISO9001-certified business, we collaborate closely with numerous foreign producers of construction, elevator, and machinery to offer them the most affordable, tailored solutions.

We are dedicated to offering top-notch metal processing services to the worldwide market and continuously work to raise the caliber of our goods and services, all while upholding the idea that our bracket solutions should be used everywhere.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

How to cut accurately?

Accurate cutting is a key link in sheet metal processing, which determines the quality and dimensional accuracy of the final product. The following are some commonly used precision cutting technologies in sheet metal processing:

Laser cutting

Principle: Use a high-power laser beam to melt the metal and make precise cuts.

Advantages:

High cutting accuracy, the error can be controlled within ±0.1mm.

Suitable for cutting complex shapes and small holes.

Efficient processing for materials such as stainless steel, carbon steel, and aluminum alloy.

Typical applications: elevator guide rail brackets, decorative metal plates, etc.

CNC stamping and cutting

Principle: The punch press is controlled by a CNC program to stamp and form metal sheets.

Advantages:

Fast cutting speed, suitable for mass production.

Diversified molds can produce standardized shapes and apertures.

Typical applications: mechanical installation gaskets, pipe clamps, etc.

Plasma cutting

Principle: High-temperature plasma is generated by high-speed airflow and arc to melt and cut the metal.

Advantages:

Strong ability to cut thick plates, can handle metal sheets over 30mm

Low cost, suitable for mass cutting.

Typical applications: large mechanical parts, building steel plate support structures.

Water jet cutting

Principle: Use high-pressure water flow (can be mixed with abrasive) to cut metal.

Advantages:

No heat effect, maintain the physical properties of the material.

Can process stainless steel, aluminum, copper and other materials.

Typical applications: complex parts with high requirements, such as automotive metal accessories.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation