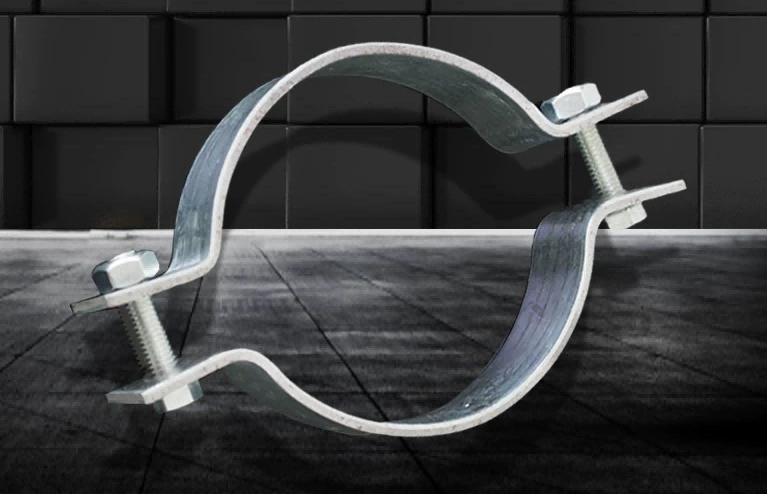

Custom Galvanized Pipe Clamp Pipe Fixing Bracket

Description

Pipe Support Bracket dimensions for pipe diameter 250 mm

● Total length: 322 mm

● Width: 30 mm

● Thickness: 2 mm

● Hole spacing: 298 mm

|

Model No. |

Pipe Diameter Range |

Width |

Thickness |

Weight |

|

001 |

50-80 |

25 |

2 |

0.45 |

|

002 |

80-120 |

30 |

2.5 |

0.65 |

|

003 |

120-160 |

35 |

3 |

0.95 |

|

004 |

160-200 |

40 |

3.5 |

1.3 |

|

005 |

200-250 |

45 |

4 |

1.75 |

| Product Type | Metal structural products | |||||||||||

| One-Stop Service | Mold development and design → Material selection → Sample submission → Mass production → Inspection → Surface treatment | |||||||||||

| Process | Laser cutting → Punching → Bending | |||||||||||

| Materials | Q235 steel, Q345 steel, Q390 steel, Q420 steel,304 stainless steel, 316 stainless steel,6061 aluminum alloy, 7075 aluminum alloy. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Building beam structure, Building pillar, Building truss, Bridge support structure, Bridge railing, Bridge handrail, Roof frame, Balcony railing, Elevator shaft, Elevator component structure, Mechanical equipment foundation frame, Support structure, Industrial pipeline installation, Electrical equipment installation, Distribution box, Distribution cabinet, Cable tray, Communication tower construction, Communication base station construction, Power facility construction, Substation frame, Petrochemical pipeline installation, Petrochemical reactor installation, etc. | |||||||||||

Benefits of Application

Corrosion resistance: Pipe Clamp employs stainless steel or galvanized surface treatment, which can tolerate severe weather conditions, especially outside.

Simple setup: Easy to assemble, quick and simple, and flexible enough to accommodate pipes of varying diameters.

High load-bearing capacity: It can sustain pipes with bigger diameters and provide secure operation when subjected to high loads.

Common application areas of Pipe Clamp

Building and Infrastructure

Provide a stable and durable support system for fixed water pipes, gas pipes, cable ducts, high-rise buildings, and underground pipe networks in construction projects. Steel Pipe Clamp, Galvanized Pipe Clamp or Carbon Steel Pipe Clamp can ensure the stability of pipes during construction and use, and prevent vibration and displacement.

Industry of Power and Communications

Large pipes, communication cables, and outside poles are all fixed and protected with Pipe Clamps in the power and communications industry. Pipe Clamps are particularly good in withstanding corrosion and erosion from wind and rain in tough outdoor conditions.

Industrial Manufacturing and Petrochemicals

In industrial environments such as factories and refineries, Pipe Clamp is used to support large-diameter industrial pipelines to transport liquids, gases or chemicals. These brackets must be able to withstand high temperatures, pressures and chemical corrosion, and Pipe Clamp made of special materials still performs well under these conditions.

Transportation and Bridge Construction

In transportation projects, Pipe Clamp can also be used to fix and support pipelines, guardrails and related facilities in bridge construction. It helps to fix and protect key facilities such as oil pipelines and drainage pipes to ensure their long-term operation safety.

Municipal Engineering

In municipal infrastructure construction, Pipe Clamp is often used to fix street lamp posts and urban water supply and sewage pipe systems. It can effectively improve the stability and safety of urban pipe networks.

Production process

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Our Advantages

Personalized design: Provide personalized design services, which can transform customers' design concepts into actual products to meet customers' unique needs.

Flexible production: Flexible production arrangements can be made according to customers' order volume and delivery period. Whether it is a small batch of customized orders or a large batch of production orders, they can be completed efficiently.

Multi-link inspection: From the incoming inspection of raw materials, to the process inspection during the processing, to the final inspection of the finished product, each link is strictly inspected for quality.

Advanced testing equipment: Equipped with high-precision testing instruments, such as three-coordinate measuring machines, hardness testers, metallographic analyzers, etc. Accurately test and analyze the size, hardness, metallographic structure, etc. of the product.

Quality traceability system: Establish a complete quality traceability system, with detailed production records and quality inspection reports for each product. The root cause of the problem can be found in time and solved at the first time.

Packaging and Delivery

Angle Steel Bracket

Right-angle Steel Bracket

Guide Rail Connecting Plate

Elevator Installation Accessories

L-shaped Bracket

Square Connecting Plate

FAQ

Q: Is your laser cutting equipment imported?

A: We have advanced laser cutting equipment, some of which are imported high-end equipment.

Q:How accurate is it?

A:Our laser cutting precision can attain an extremely high degree, with errors often occurring within ±0.05mm.

Q:How thick of a sheet of metal can be cut?

A: It is capable of cutting metal sheets with varying thicknesses, ranging from paper-thin to several tens of millimeters thick. The kind of material and the equipment model determine the precise thickness range that can be cut.

Q: After laser cutting, how is the edge quality?

A: There is no need for further processing because the edges are burr-free and smooth after cutting. It is highly guaranteed that the edges are both vertical and flat.