Corrosion-Resistant Elevator Sill Bracket with Customizable Design

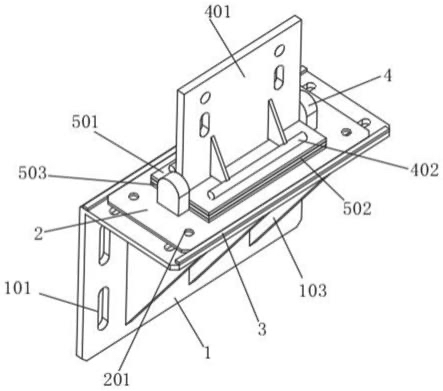

● Length: 200 mm

● Width: 60 mm

● Height: 50 mm

● Thickness: 3 mm

● Hole length: 65 mm

● Hole width: 10 mm

● Product type: elevator accessories

● Material: stainless steel, carbon steel

● Process: laser cutting, bending

● Surface treatment: galvanizing, anodizing

● Application: fixing, connecting

● Weight: about 2.5KG

What types of elevator sill brackets are there?

Fixed sill brackets:

● Welded type: The various parts of this sill bracket are connected together by welding to form a whole. The advantages are high structural strength, firm connection, ability to withstand large weight and impact force, and not easy to deform or loosen. It is often used in elevators with high requirements for stability and safety, such as elevators in some large shopping malls, high-rise office buildings and other places. However, once the welding of the welded bracket is completed, its shape and size are difficult to adjust. If problems such as dimensional deviation are found during the installation process, it will be more troublesome to adjust.

● Bolt-on type: The various parts of the sill bracket are connected and fixed by bolts. This type of bracket has a certain degree of detachability, which is convenient for assembly and disassembly during installation and maintenance. If a component is damaged or needs to be replaced, the component can be disassembled separately for repair or replacement without replacing the bracket as a whole, reducing maintenance costs. At the same time, the bolt connection method also allows fine-tuning within a certain range to adapt to slight deviations in the elevator shaft or car structure.

Adjustable upper sill bracket:

● Horizontal adjustment type: The bracket is equipped with a horizontal adjustment device, which can adjust the position of the bracket in the horizontal direction. For example, if the wall of the elevator shaft is uneven, the correct installation position of the upper sill bracket and the elevator door can be ensured by horizontal adjustment, so that the elevator door can be opened and closed smoothly. This type of bracket is suitable for elevator shafts with more complex installation environments, which improves the adaptability and flexibility of elevator installation.

● Longitudinal adjustment type: It can be adjusted in the vertical direction to meet the installation requirements of elevator doors of different heights. During the elevator installation process, if there is a difference between the height of the elevator door and the initial installation height of the upper sill bracket, the matching degree between the upper sill bracket and the elevator door can be ensured by longitudinal adjustment to ensure the normal operation of the elevator door.

● All-round adjustment type: It combines the functions of horizontal adjustment and vertical adjustment, and can adjust the position in multiple directions. This bracket has a wider adjustment range and higher flexibility, which can meet the installation requirements of elevator upper sills under various complex installation conditions, greatly improving the efficiency and accuracy of elevator installation.

Special function upper sill bracket:

● Anti-slip type: In order to improve the safety of the elevator and prevent the elevator door hanging plate assembly from falling off the upper sill bracket when it is impacted by external force, an upper sill bracket with an anti-slip function is designed. This bracket is usually specially designed in structure, such as adding additional limit devices, using special guide rail shapes, etc., which can effectively limit the movement range of the door hanging plate assembly.

● Upper sill bracket suitable for special door types: For some special elevator door types, such as side-opening tri-fold doors, center-split bi-fold doors, etc., specially designed upper sill brackets are required to match them. The shape, size and guide rail structure of these brackets are optimized according to the characteristics of special door types to ensure the normal opening and closing and operation of the door.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 and focuses on the production of high-quality metal brackets and components, which are widely used in the construction, elevator, bridge, power, automotive parts and other industries. The main products include seismic pipe gallery brackets, fixed brackets, U-channel brackets, angle brackets, galvanized embedded base plates, elevator mounting brackets and fasteners, etc., which can meet the diverse project needs of various industries.

The company uses cutting-edge laser cutting equipment in conjunction with bending, welding, stamping, surface treatment, and other production processes to guarantee the precision and longevity of the products.

As an ISO 9001 certified company, we have worked closely with many international machinery, elevator and construction equipment manufacturers and provide them with the most competitive customized solutions.

According to the company's "going global" vision, we are dedicated to offering top-notch metal processing services to the global market and are constantly working to improve the quality of our products and services.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

How to choose the right sill bracket for your elevator?

According to theTtype and Purpose of the Elevator

● Passenger elevators: used in places such as residences, office buildings or shopping malls, with high requirements for comfort and safety. When choosing a sill bracket, give priority to products with good stability and precise guidance, such as adjustable sill brackets, which can reduce operating vibration and noise and ensure a comfortable experience for passengers.

● Cargo elevators: Because they need to carry heavy objects, the doors are relatively heavy. It is necessary to choose a sill bracket with strong load-bearing capacity, such as a welded fixed sill bracket, which has high structural strength and can withstand large weight and impact force to ensure that the elevator door works normally during frequent loading and unloading of goods.

● Medical elevators: Hygiene and barrier-free access need to be considered. The bracket material should be corrosion-resistant and easy to clean, and the elevator door should be opened and closed accurately. A sill bracket with precise adjustment function can be selected to facilitate adjustment according to actual conditions.

Elevator door type and size

● Door type: Different types of elevator doors (such as center-split bifold doors, side-opening bifold doors, vertical sliding doors, etc.) have different requirements for the shape of the bracket and the guide rail structure. It is necessary to select a matching sill bracket according to the specific type of door. For example, a center-split bi-fold door requires a bracket guide rail that allows the door leaf to open and close symmetrically in the middle, while a side-open bi-fold door requires a guide rail to guide the door leaf to open to one side.

● Door size: The size of the elevator door affects the size and load-bearing capacity of the sill bracket. For large elevator doors, it is necessary to select a sill bracket with large size and strong load-bearing capacity, and determine whether its structural strength is sufficient according to the door weight. For example, the glass door of a large sightseeing elevator is large and heavy, so it is necessary to select a fixed sill bracket that can withstand a large weight, and the material and process must meet the standards.

Elevator shaft environment

● Space and layout: If the elevator shaft space is narrow or the layout is irregular, an adjustable (especially all-round adjustable) sill bracket is more suitable. It can be adjusted in different directions to adapt to special conditions of the shaft.

● Wall conditions: When the wall is uneven, a sill bracket with an adjustable function should be selected to facilitate horizontal and vertical adjustments during installation to avoid problems with the installation or operation of the elevator door due to wall problems.

Safety requirements

For places with high safety requirements (such as high-rise buildings, hospitals, etc.), a sill bracket with an anti-slip function should be selected to prevent the elevator door panel assembly from falling off due to external impact and ensure the safe operation of the elevator. At the same time, it is necessary to ensure that the bracket meets the relevant elevator safety standards and specifications, such as GB 7588-2003 "Safety Specifications for Elevator Manufacturing and Installation" and other national standards.

Budget and cost

The prices of sill brackets of different types and brands vary greatly. Considering the budget under the premise of meeting performance and safety requirements, the price of fixed sill brackets is relatively low, while the price of adjustable and special function types is higher. However, you cannot choose products of poor quality or non-compliant products in order to reduce costs, otherwise it will increase the subsequent maintenance costs and safety risks. You can consult multiple suppliers and make a reasonable choice after comparing prices and cost-effectiveness.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation