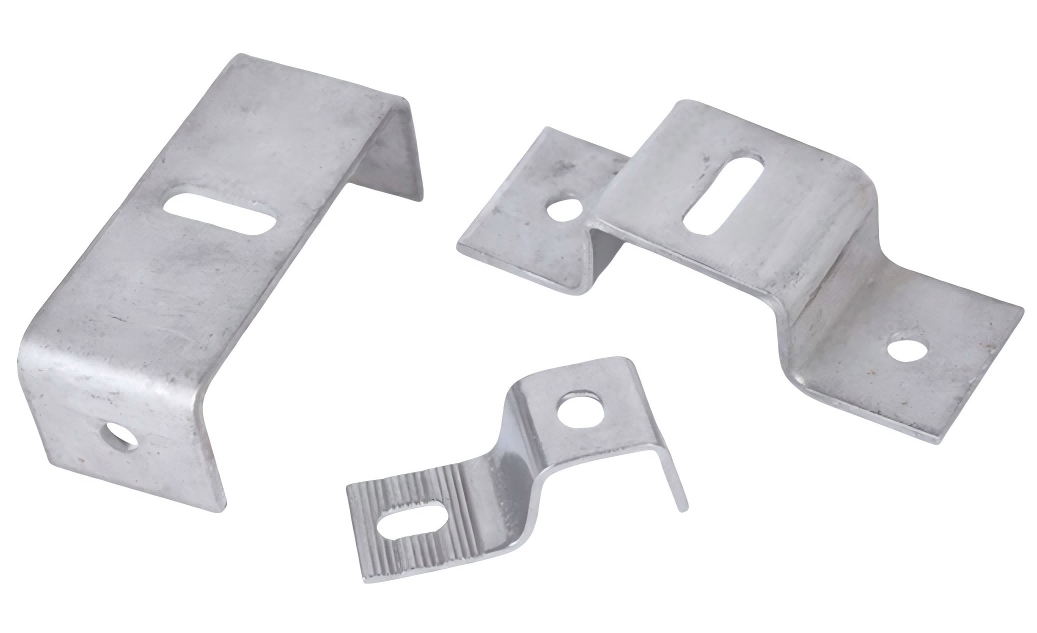

Building construction carbon steel fixings curtain wall mounting bracket

● Products: OEM, custom metal products

● Process: Laser Cutting, Bending, Stamping

● Product material: Carbon steel, Alloy steel,Stainless steel, Galvanized steel

● Surface treatment: Deburring, Galvanizing

Wall Panel Mounting Bracket Application Areas

Building facades: Curtain wall systems for commercial complexes and high-rise buildings.

Shopping malls: Provide structural stability and aesthetic appeal.

Residential communities: Improve the durability and aesthetics of high-rise residential structures.

Industrial buildings: External wall support for factories and warehouses.

Bridges and tunnels: Support aids for certain designed structures.

Advantages of Wall Mount Brackets

Structural stability

The bracket is made of high-strength materials and is designed to withstand large wind loads and external forces such as earthquakes, ensuring the overall stability of the curtain wall system and preventing tilting or falling due to external factors. This stability is particularly important for high-rise buildings and can effectively ensure the safety of the building.

Aesthetics

It can be combined with a variety of facade materials (such as glass, aluminum alloy, stone, etc.) to support the design concept of modern buildings and enhance the aesthetics of the appearance. Whether it is a simple style or a complex geometric shape, the curtain wall bracket can provide support to meet the designer's creative requirements.

Weather resistance

The use of corrosion-resistant materials (such as hot-dip galvanized steel or aluminum alloy) can withstand various weather conditions, including wind and rain, ultraviolet rays and temperature changes, reducing maintenance frequency and costs and extending service life. Its weather resistance ensures that the building can still maintain good appearance and function in harsh climates.

Flexibility

The design of the curtain wall bracket can adapt to different building forms and sizes, and has a high degree of flexibility.

Load reduction

It can effectively disperse the weight of the facade and reduce the burden on the main structure of the building.

Energy saving

To increase the building's thermal insulation performance and lower energy consumption, several curtain wall bracket systems are paired with energy-efficient insulation and designs. Energy conservation can be accomplished by using less heating and cooling, which is consistent with the idea of contemporary green buildings.

Easy maintenance

The design of the bracket allows technicians to easily reach various parts when inspecting and cleaning the curtain wall, improving work efficiency and reducing the complexity and cost of maintenance.

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Company Profile

Xinzhe Metal Products Co., Ltd. was established in 2016 with the intention of manufacturing superior metal brackets and parts that are widely used in a variety of industries, including the construction, power, elevator, bridge, and automotive sectors. Steel structure connections, elevator mounting brackets, fixed brackets, angle steel brackets, galvanized embedded base plates, mechanical equipment brackets, mechanical equipment gaskets, etc. are among the primary goods.

The business uses cutting-edge laser cutting technology in conjunction with bending, welding, stamping, surface treatment, and other production techniques to guarantee the precision and longevity of the products.

As an ISO 9001 certified factory, we work closely with many global construction, elevator and mechanical equipment manufacturers to create tailor-made solutions.

Adhering to the vision of "becoming a global leading sheet metal processing bracket solution provider", we continue to improve product quality and service level.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Our prices are determined by workmanship, materials and other market factors.

After your company contacts us with drawings and required material information, we will send you the latest quotation.

Q: What is the minimum order quantity?

A: The minimum order quantity for our small products is 100 pieces, while the minimum order number for large products is 10.

Q: How long do I have to wait for shipment after placing an order?

A: Samples can be supplied in approximately 7 days.

Mass-produced goods will ship within 35-40 days after receiving the deposit.

If our delivery schedule does not match your expectations, please voice an issue when inquiring. We will do everything we can to fulfill your requirements.

Q: What are the payment methods you accept?

A: We accept payments via bank account, Western Union, PayPal, and TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation