Big discounting Customized Sheet Metal Fabrication Stamping Punching Forming Parts for Elevator Accessories

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” and the theory of “quality the basic, belief the very first and management the advanced” for Big discounting Customized Sheet Metal Fabrication Stamping Punching Forming Parts for Elevator Accessories, We give priority to good quality and customer fulfillment and for this we follow stringent excellent control measures. We’ve in-house testing facilities where our goods are tested on each and every aspect at different processing stages. Owning to latest technologies, we facilitate our prospects with custom-made production facility.

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” and the theory of “quality the basic, belief the very first and management the advanced” for Industrial Parts and Deep Drawing, We now have a specialist sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with individualized service and unique items.

Description

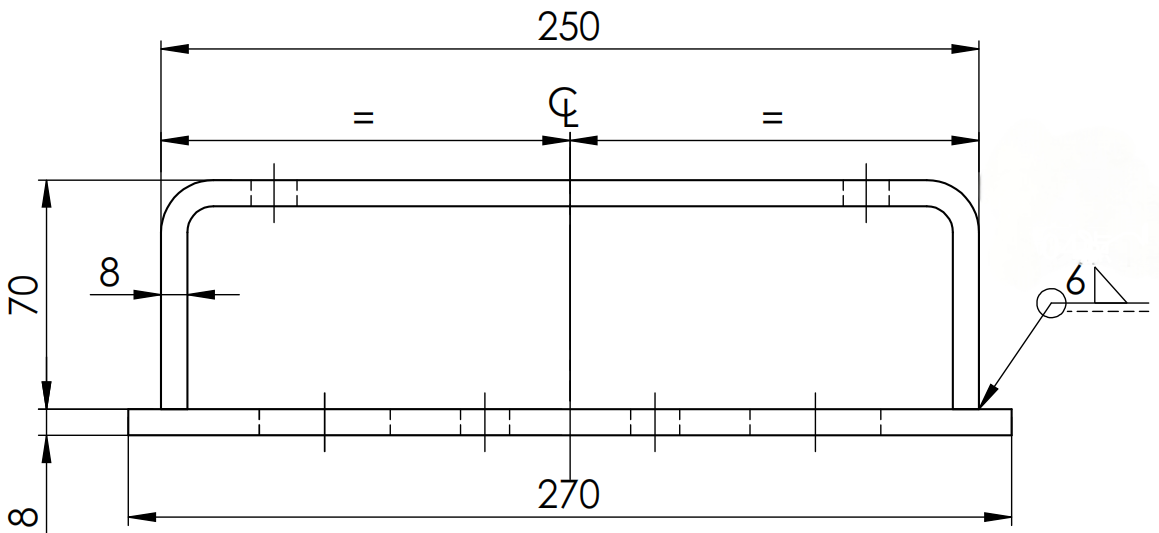

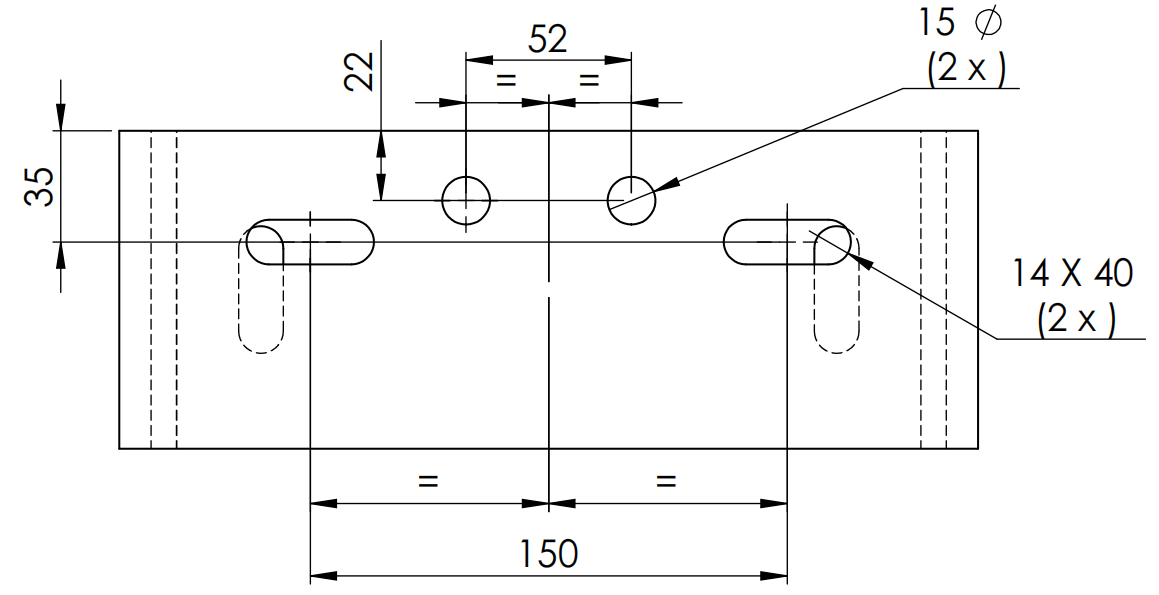

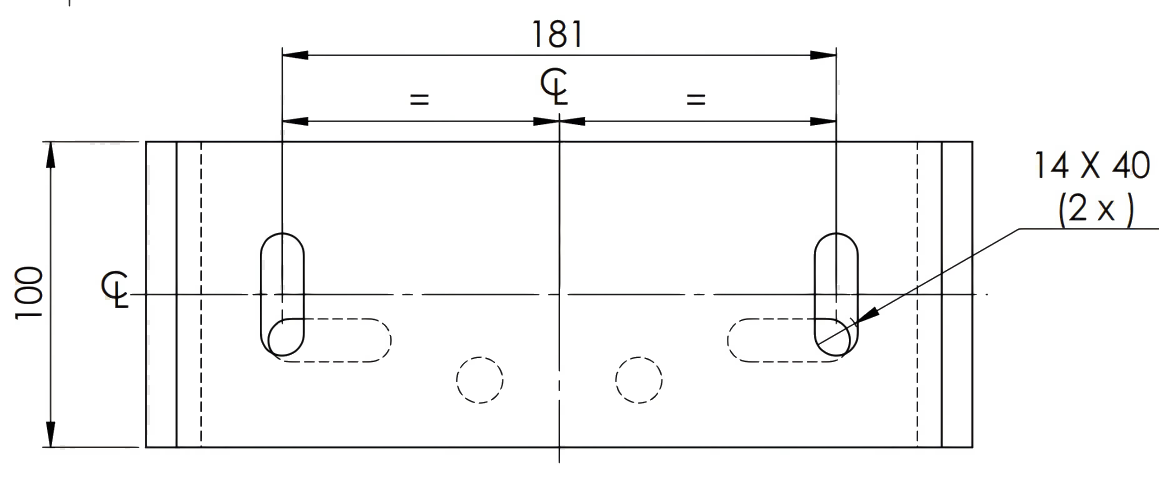

● Product Type: Customized product

● Process: Laser cutting, bending, welding.

● Material: Carbon steel Q235

● Surface Treatment: Spraying RAL 5017

APPLICABLE ELEVATOR

APPLIED BRANDS

Why Are Guide Shoes Kit in Elevator Installation?

The elevator guide shoes and guide shoe shell base are installed on the car and counterweight device, just like the “navigator” for the smooth operation of the elevator. They ensure that the elevator moves accurately along the guide rail in the vertical direction, prevent shaking and derailment, and provide passengers with a safe and comfortable riding experience. The installation accessories are the key support to ensure the normal function of the guide shoes.

The role of metal brackets in elevator installation

Structural support

As the basic framework for the installation of guide shoes, the support bracket provides stable support for the guide shoes to ensure that they will not deform or displace during operation. It can withstand various forces generated during the operation of the elevator, including gravity, inertial force, etc.

Protection function

The anti-seismic bracket can provide good protection for the guide shoes and other internal components. It can resist external impact, collision and the intrusion of impurities such as dust and moisture, and extend the service life of the guide shoes and other accessories.

Installation and fixing

Through precise design and processing, various mounting holes and fixing points are provided on the fixing bracket, which is convenient for connection and fixing with the elevator car, counterweight device and guide rails. Ensure that the guide shoe is installed firmly and reliably, and will not loosen or fall off during operation.

Synergy of other installation accessories

In addition to the sheet metal bracket, the elevator guide shoe installation accessories also include guide shoe bushings, fixing bolts, adjustment gaskets, etc.

Installation and maintenance points

Professional installation

The installation of elevator guide shoes and accessories must be performed by professional technicians and strictly in accordance with the installation specifications of the elevator manufacturer. Ensure that the installation position of the bracket is accurate, fixed firmly, and highly accurate with other accessories.

Regular inspection

In order to ensure the safe operation of the elevator, it is necessary to regularly inspect the guide shoes and installation accessories. Check whether the installation parts are deformed, corroded or damaged, and replace the worn parts in time.

Quality Management

Packaging and Delivery

Company Profile

Professional technical team

Xinzhe has a professional team of senior engineers, technicians and skilled workers who have accumulated rich experience in the field of sheet metal processing. They can accurately understand the needs of customers.

Continuous innovation

We keep an eye on the latest technology and development trends in the industry, actively introduce advanced processing equipment and processes, and carry out technological innovation and improvement. In order to provide customers with better quality and more efficient processing services.

Strict quality management system

We have established a complete quality control system (ISO9001 certification has been completed), and strict quality inspections are carried out in every link from raw material procurement to production and processing. Ensure that the quality of the product meets international standards and customer requirements.

FAQ

Q: How can I get a quote?

A: Our prices are determined by process, materials and other market factors.

After your company contacts us with drawings and required material information, we will send you the latest quotation.

Q: What is your minimum order quantity?

A: Our minimum order quantity for small products is 100 pieces and for large products is 10 pieces.

Q: How long can I wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

For mass-produced products, they will be shipped within 35-40 days after receiving the deposit.

If our delivery time is inconsistent with your expectations, please raise your objection when inquiring. We will do everything we can to meet your needs.

Q: What payment methods do you accept?

A: We accept payment via bank account, Western Union, PayPal or TT.

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” and the theory of “quality the basic, belief the very first and management the advanced” for Big discounting Customized Sheet Metal Fabrication Stamping Punching Forming Parts for Elevator Accessories, We give priority to good quality and customer fulfillment and for this we follow stringent excellent control measures. We’ve in-house testing facilities where our goods are tested on each and every aspect at different processing stages. Owning to latest technologies, we facilitate our prospects with custom-made production facility.

Big discounting Industrial Parts and Deep Drawing, We now have a specialist sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with individualized service and unique items.