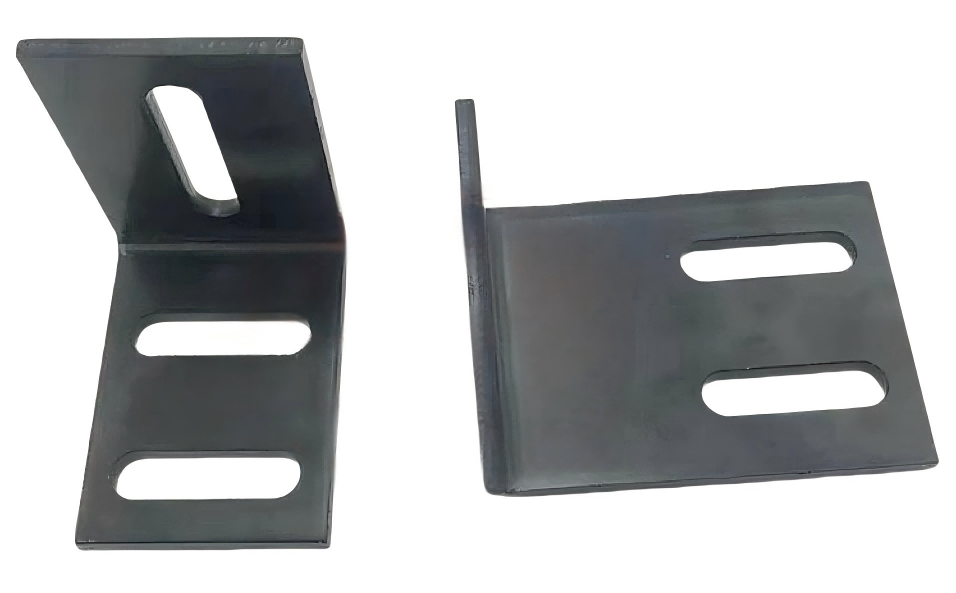

Anodized elevator sill bracket for Hitachi elevators

● Length: 60 mm

● Width: 45 mm

● Height: 60 mm

● Thickness: 4 mm

● Hole length: 33 mm

● Hole width: 8 mm

● Length: 80 mm

● Width: 60 mm

● Height: 40 mm

● Thickness: 4 mm

● Hole length: 33 mm

● Hole width: 8 mm

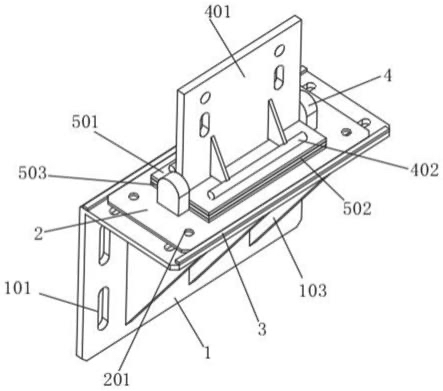

● Product type: elevator accessories

● Material: stainless steel, carbon steel, alloy steel

● Process: laser cutting, bending

● Surface treatment: galvanizing, anodizing

● Application: fixing, connection

● Installation method: fastener connection

The Development History of Elevator Sill Brackets

Early 20th century:

Elevator technology was gradually popularized. Early sill brackets were mainly steel frame structures with simple designs. Their main function was to support the weight of the elevator door sill and maintain the basic stability of the elevator entrance and exit. Most brackets at this stage were fixed and could not adapt to different elevator models or specific building requirements.

Mid-20th century:

As the application range of elevators expanded, especially in high-rise buildings, the stability and safety of elevator operation became key issues.

Sill brackets began to use high-strength steel and were galvanized or anti-corrosion treated to extend their service life.

The structural design was further optimized, such as adding multi-point fixation and shock-absorbing structures to reduce vibration and noise during elevator operation.

During this period, the standardization of brackets began to emerge, and some countries and industries formulated clear production specifications.

Late 20th century:

The elevator manufacturing industry ushered in rapid development, and the demand for different types of elevators (residential, commercial, industrial) promoted the diversified design of sill brackets.

The bracket design transitioned from unified to customized to meet the threshold requirements of different brands and installation environments.

Modular design makes bracket installation more convenient, while reducing maintenance and replacement costs.

In terms of materials, stainless steel and lightweight alloy materials are gradually becoming popular, combining durability and aesthetics.

From the 21st century to the present:

Modern elevator technology is transforming towards intelligent and green manufacturing, and the upper sill bracket has also entered a new stage of development.

Intelligent bracket: Some brackets are integrated with sensors, which can monitor the load and operating status of the elevator door sill in real time to improve safety.

Environmentally friendly materials: In response to the needs of sustainable development, recyclable materials are introduced into bracket manufacturing, and the production process is optimized to reduce carbon emissions.

Lightweight design: Combined with CAE (computer-aided engineering) optimization, the bracket design can not only meet high-strength requirements, but also reduce overall weight and improve energy efficiency.

Future Trend Outlook

The development of elevator upper sill brackets will pay more attention to intelligence, customization and eco-friendliness. It must not only meet the technical needs of the elevator industry, but also take into account aesthetics and environmental protection values, helping modern buildings achieve higher safety and convenience.

Applicable Elevator Brands

● Otis

● Schindler

● Kone

● TK

● Mitsubishi Electric

● Hitachi

● Fujitec

● Hyundai Elevator

● Toshiba Elevator

● Orona

● Xizi Otis

● HuaSheng Fujitec

● SJEC

● Cibes Lift

● Express Lift

● Kleemann Elevators

● Giromill Elevator

● Sigma

● Kinetek Elevator Group

Quality Management

Vickers Hardness Instrument

Profile Measuring Instrument

Spectrograph Instrument

Three Coordinate Instrument

Our Services

From simple fixed structures to intelligent and environmentally friendly designs, the development of sill brackets reflects the elevator industry's growing emphasis on safety, durability and adaptability. However, even with the continuous advancement of technology, there are still many challenges in the market, such as uneven bracket quality, insufficient installation adaptability, and reliability issues after long-term use.

At Xinzhe Metal Products, we are keenly aware of these industry needs and focus on providing customers with high-quality elevator sill bracket solutions. Through precision manufacturing and strict quality control, our brackets have the following advantages:

● Precise adaptation: fully compatible with mainstream elevator brands (such as Otis, KONE, Schindler, TK, etc.), and can provide customized services according to customer needs.

● High-quality materials: stainless steel or galvanized steel is used to ensure corrosion resistance, load resistance and long-term stability.

● Passed ISO 9001:2015 quality management system certification, our products strictly follow international quality standards to ensure excellent quality and reliable performance.

● High cost performance: at an affordable price, we provide you with product quality that far exceeds your expectations.

We are well aware that each elevator bracket is not just a component, but also an important guarantee for building safety and user experience. Therefore, Xinzhe always takes the high standards of industry development as a benchmark, continuously improves its own process level, and creates reliable and durable bracket products for customers.

Packaging and Delivery

Angle Steel Brackets

Elevator Guide Rail Connection Plate

L-shaped Bracket Delivery

Angle Brackets

Elevator Mounting Kit

Elevator Accessories Connection Plate

Wooden Box

Packing

Loading

FAQ

Q: How to get a quote?

A: Just send your drawings and required materials to our email or WhatsApp, and we will provide you with the most competitive quote as soon as possible.

Q: What is your minimum order quantity?

A: The minimum order quantity for our small products is 100 pieces, and the minimum order quantity for large products is 10 pieces.

Q: How long do I have to wait for delivery after placing an order?

A: Samples can be sent in about 7 days.

Mass production products are 35 to 40 days after payment.

Q: What is your payment method?

A: We accept payments through bank accounts, Western Union, PayPal or TT.

Multiple Transportation Options

Ocean Freight

Air Freight

Road Transportation