COMPANY PROFILE

Ningbo Xinzhe Metal Products Co., Ltd. is located in Ningbo, Zhejiang Province, China. The factory covers an area of 2,800 square meters, with a construction area of 3,500 square meters. Currently, there are more than 30 employees. We are China's leading sheet metal processing supplier.

Since its establishment in 2016, the company has worked hard in practice and has not only accumulated extremely rich knowledge and superb technical experience, but also trained a group of outstanding technical engineers and employees in various process departments.

Xinzhe's main processing technologies are: laser cutting, shearing, CNC bending, progressive die stamping, stamping, welding, riveting.

Surface treatment processes include: electroplating, powder spraying/spraying, oxidation, electrophoresis, polishing/brushing, hot-dip galvanizing.

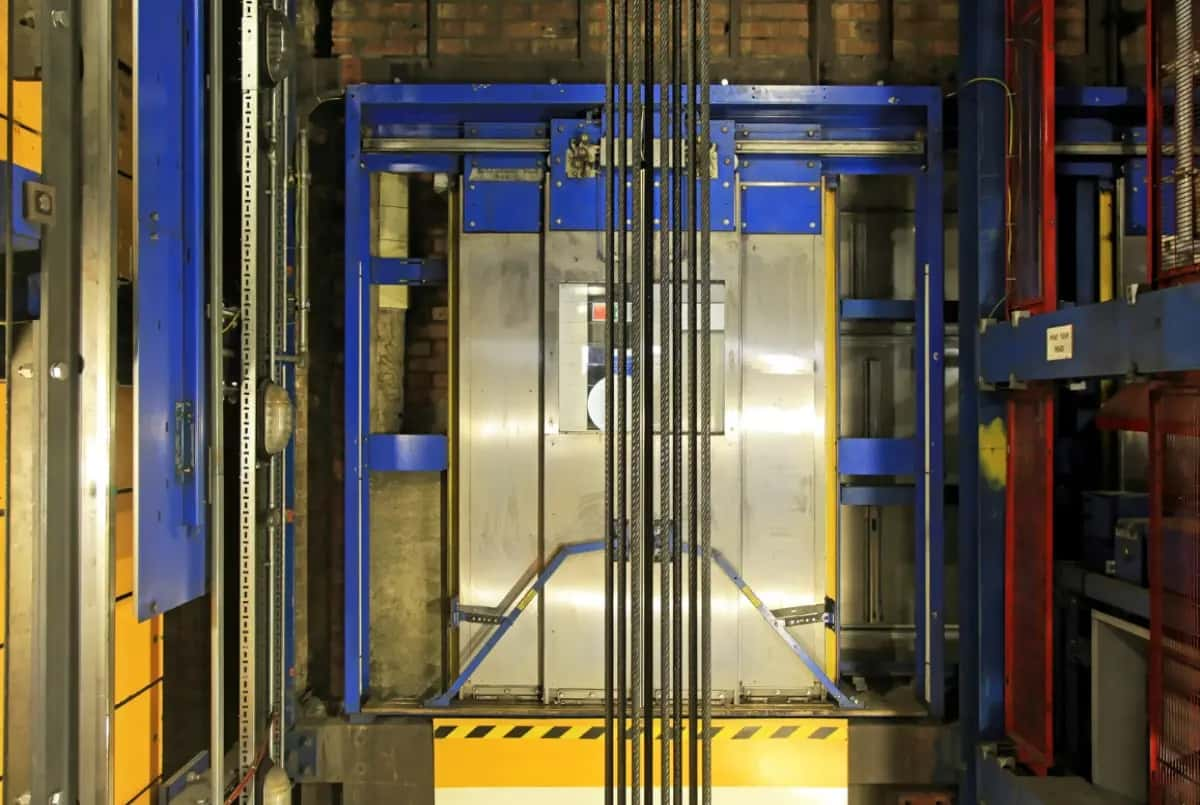

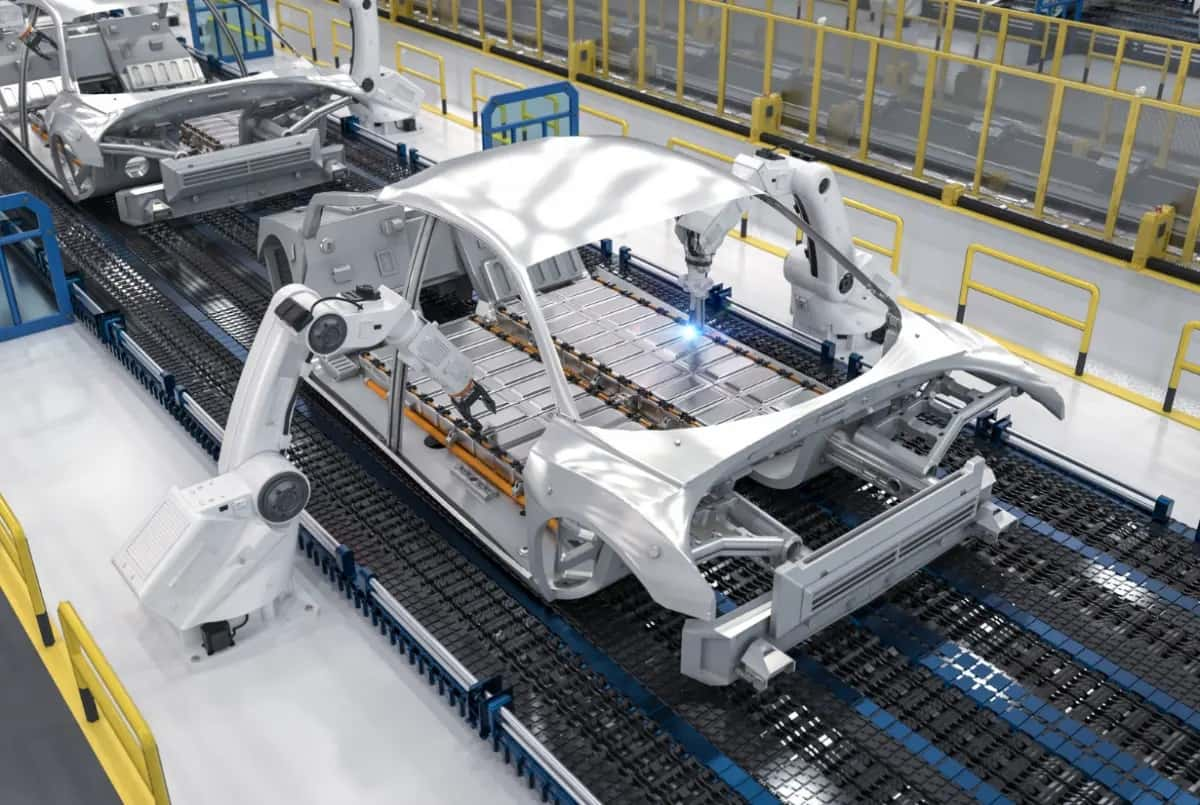

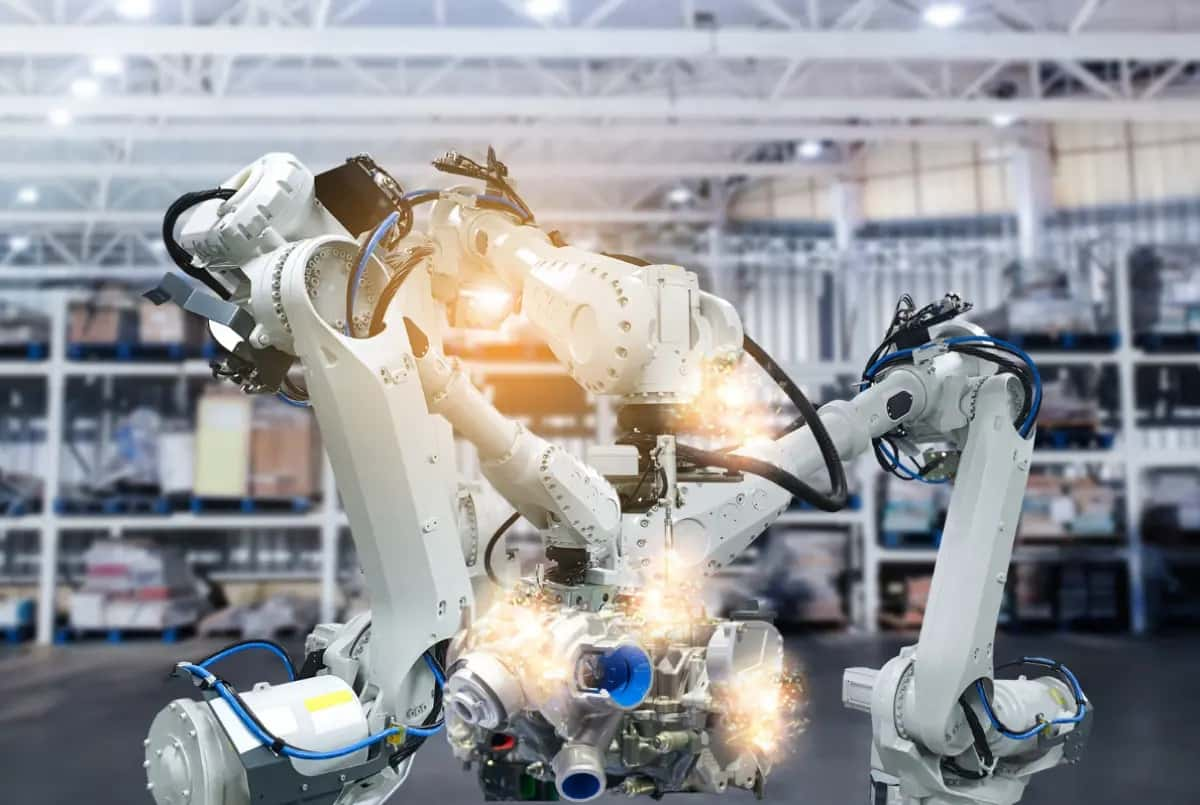

The company's main products include pipe brackets, cantilever brackets, seismic brackets, curtain wall brackets, steel structure connecting plates, angle steel brackets, cable trough brackets, elevator Brackets, elevator shaft fixed brackets, track brackets, metal slotted shims, Turbo Wastegate Bracket, metal anti-slip pads and other sheet metal processing parts. At the same time, we provide fastener accessories such as DIN 933, DIN 931, DIN 912, DIN 125, DIN 127, DIN 985, DIN 7985, DIN 6923, DIN6921, etc. which are widely used in construction, garden construction, elevator installation, automobile manufacturing, mechanical equipment installation, robotics and other industries.

We are dedicated to giving customers better sheet metal processing products and services, opening up a large market together, and achieving win-win cooperation. We are always making significant progress in our research and development, continuous improvement, and upgrading journeys.

Currently, numerous well-known elevator brands, including Otis, Schindler, Kone, TK, Mitsubishi, Hitachi, Fujita, Toshiba, Yongda, and Kangli, have successfully purchased elevator installation kits from our company. It has received widespread recognition and acclaim in the elevator business for its precise and high-quality customizing services. The selection of these well-known manufacturers amply demonstrates our expertise and dependability in the elevator installation kit market.

Service

Bridge construction

Steel components help the main structure of the bridge

Architecture

Provide a full range of support solutions for construction

Elevator

High-quality kits create elevator safety pillars

Mining industry

Working hand in hand with the mining industry to build a solid foundation

Aerospace Industry

Provide a full range of support solutions for construction

Auto Parts

Building a solid backbone for the automotive industry

Medical Devices

Technological tools to protect life and health require high-precision metal parts

Pipeline protection

Solid support, building a pipeline safety line of defense

Robotics Industry

Helping to start a new journey of intelligent future

Why Choose Us

Global Customization

Price is lower than other Suppliers

High-quality products

Rich experience in sheet metal processing

Timely response and delivery

Reliable after-Sales team

FAQ

Our prices are subject to change based on process, material, and other market factors.

We will send you the latest quote after your company contacts us for more information.

For samples, the shipping time is about 7 days.

For mass production, the shipping time is 35-40 days after receiving the deposit.

The shipping time is effective when:

(1) we receive your deposit.

(2) we get your final production approval for the product.

If our shipping time does not match your deadline, please raise your objection when you inquire. We will do our best to meet your needs.

We offer a warranty against defects in our materials, manufacturing process, and structural stability.

We are committed to your satisfaction and peace of mind with our products.

Whether covered by warranty or not, our company culture is to resolve all customer issues and satisfy every partner.

Yes, we usually use wooden boxes, pallets, or reinforced cartons to prevent the products from being damaged during transportation and carry out protective treatment according to the characteristics of the products, such as moisture-proof and shock-proof packaging. To ensure safe delivery to you.

The modes of transportation include sea, air, land, rail, and express, depending on the quantity of your goods.